Home

|About Us

|Product center

|company culture

|News

|Contact Us

|Helical-Coupling

|

|

|

|

| Material code | |

| Agitator shaft bore | |

| The outer diameter of the stirrer, | |

| Stirrer type code |

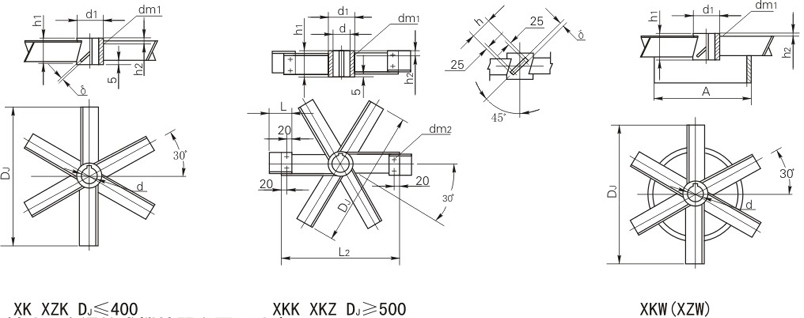

Six inclined blades open turbine agitator

Six-slanted blade integral opening turbine type XK, six-sloping blade detachable opening turbine type XKK, six-sloping blade stabilizing ring opening turbine type XKW, six-sloping narrow blade integral opening turbine type XZK, six-sloping narrow blade detachable opening turbine type XKZ, Six oblique narrow blades stable opening turbo XZW

Compared with the straight-blade open turbine type, this type of agitator has axial flow in addition to radial flow, and its shear performance is between straight and curved blades, so it has better overall performance, dispersion, solids, and suspension. , Solid dissolution are more suitable, other processes can also be applied, the operating conditions are the same as the six straight blades to turn on the turbine.

Main size table of oblique blade open turbine agitator

| DJ | d | d1 | h2 | A | L | L2 | dm1/dm2 | Wide | Narrow | δ | Wide weight | Narrow weight | ||||

| h | h1 | N/n≤ | h | h1 | N/n≤ | Carbon steel/stainless steel | ||||||||||

| 150 | 30 | 55 | 12 | 100 | - | - | M12/- | 30 | 55 | 0.008 | 20 | 50 | 0.0035 | 6/5 | 1.1/1.05 | 0.924/0.914 |

| 35 | 60 | 1.1/1.05 | 0.1/0.994 | |||||||||||||

| 200 | 30 | 55 | 12 | 140 | - | - | M12/- | 40 | 60 | 0.008 | 25 | 55 | 0.0045 | 6/5 | 1.55/1.42 | 1.233/1.186 |

| 40 | 60 | 1.57/1.44 | 1.19/1.142 | |||||||||||||

| 250 | 35 | 55 | 12 | 170 | - | - | M12/- | 50 | 70 | 0.011 | 30 | 55 | 0.008 | 6/5 | 2.67/2.44 | 1.438/1.338 |

| 40 | 70 | 2.68/2.47 | 1.946/1.868 | |||||||||||||

| 300 | 40 | 70 | 12 | 200 | - | - | M12/- | 60 | 76 | 0.018 | 40 | 70 | 0.015 | 8/5 | 4.23/3.22 | 3.12/2.562 |

| 45 | 75 | 4.26/3.29 | 3.25/2.689 | |||||||||||||

| 50 | 80 | 4.33/3.37 | 3.379/2.834 | |||||||||||||

| 400 | 45 | 80 | 12 | 270 | - | - | M12/- | 80 | 90 | 0.031 | 50 | 80 | 0.025 | 8/6 | 7.3/6.1 | 5.125/4.506 |

| 50 | 85 | 7.37/6.18 | 5.297/4.686 | |||||||||||||

| 55 | 90 | 7.54/6.37 | 5.469/4.867 | |||||||||||||

| 500 | 60 | 95 | 16 | 340 | 100 | 380 | M16/-M12 | 100 | 106 | 0.089 | 65 | 95 | 0.06 | 10/8 | 13.96/11.92 | 9.301/8.267 |

| 65 | 100 | 14.1/12.06 | 9.505/8.481 | |||||||||||||

| 70 | 105 | 14.17/12.17 | 9.710/8.696 | |||||||||||||

| 600 | 65 | 105 | 16 | 400 | 130 | 420 | M16/-M12 | 120 | 120 | 0.11 | 75 | 100 | 0.08 | 12/10 | 23.35/20.34 | 14.578/13.111 |

| 70 | 110 | 23.42/20.44 | 14.825/13.371 | |||||||||||||

| 80 | 120 | 23.66/20.74 | 15.318/13.888 | |||||||||||||

| 700 | 70 | 115 | 16 | 470 | 180 | 420 | M16/-M12 | 140 | 140 | 0.15 | 90 | 110 | 0.1 | 12/10 | 31.75/27.7 | 20.271/18.193 |

| 80 | 120 | 32.33/28.3 | 20.881/18.834 | |||||||||||||

| 90 | 135 | 32.36/28.47 | 21.492/19.475 | |||||||||||||

| 800 | 75 | 120 | 18 | 540 | 200 | 480 | M16/-M12 | 160 | 160 | 0.23 | 100 | 120 | 0.18 | 14/12 | 42.97/39.93 | 27.91/26.08 |

| 85 | 140 | 46.53/43.66 | 30.58/28.87 | |||||||||||||

| 95 | 160 | 49.74/47.00 | 32.96/31.38 | |||||||||||||

| 900 | 80 | 130 | 18 | 600 | 250 | 480 | M16/-M12 | 180 | 180 | 0.26 | 115 | 130 | 0.21 | 14/12 | 55.69/51.25 | 35.96/33.62 |

| 90 | 150 | 60.02/55.58 | 39.08/36.9 | |||||||||||||

| 100 | 160 | 61.20/56.76 | 39.94/37.8 | |||||||||||||

| 1000 | 90 | 150 | 18 | 670 | 300 | 480 | M16/-M12 | 200 | 200 | 0.29 | 125 | 150 | 0.23 | 14/12 | 72.48/67.96 | 42.52/44.16 |

| 100 | 160 | 73.79/69.34 | 48.5/45.86 | |||||||||||||

| 110 | 180 | 79.75/75.6 | 52.97/50.55 | |||||||||||||

| 1120 | 100 | 160 | 20 | 750 | 360 | 480 | M18 / M16 | 225 | 225 | 0.43 | 140 | 160 | 0.34 | 16/14 | 99.93/94.65 | 64.34/61.08 |

| 110 | 180 | 106.6/101.7 | 69.11/66.09 | |||||||||||||

| 120 | 190 | 108.6/103.7 | 70.49/67.54 | |||||||||||||

| 1250 | 110 | 180 | 20 | 840 | 430 | 480 | M18 / M16 | 250 | 250 | 0.47 | 160 | 180 | 0.38 | 16/14 | 130.2/123.8 | 84.33/80.54 |

| 120 | 190 | 132.3/126.1 | 85.88/82.17 | |||||||||||||

| 130 | 200 | 134.5/128.3 | 87.44/83.8 | |||||||||||||

| 1400 | 120 | 190 | 20 | 940 | 500 | 480 | M18 / M16 | 280 | 280 | 0.53 | 175 | 196 | 0.42 | 16/14 | 163/154.8 | 103.9/98.87 |

| 130 | 200 | 165.5/157.3 | 105.5/100.5 | |||||||||||||

| 140 | 210 | 167.9/159.9 | 107.2/102.3 | |||||||||||||

| 1600 | 130 | 200 | 25 | 1070 | 300 | 480 | M18 / M16 | 320 | 320 | 0.77 | 200 | 200 | 0.62 | 18/16 | 232.8/222.6 | 145.5/137.7 |

| 140 | 210 | 235.5/225.5 | 147.2/140.9 | |||||||||||||

| 150 | 220 | 238.3/228.4 | 148.9/142.7 | |||||||||||||

| 1800 | 140 | 210 | 25 | 1200 | 720 | 480 | M18 / M16 | 360 | 360 | 0.86 | 225 | 210 | 0.69 | 18/16 | 294/283.8 | 181.5/171.5 |

| 150 | 220 | 297.1/287 | 183.3/175 | |||||||||||||

| 160 | 240 | 310.7/301.3 | 191.2/183.3 | |||||||||||||

| 2000 | 150 | 220 | 25 | 1340 | 820 | 480 | M20 / M18 | 400 | 400 | 0.96 | 250 | 240 | 0.77 | 18/16 | 363.8/344.4 | 224.9/214.4 |

| 160 | 240 | 378.8/360.2 | 233.9/223.9 | |||||||||||||

| 170 | 250 | 382.7/364.3 | 236.3/226.4 | |||||||||||||

| 2240 | 160 | 240 | 30 | 1500 | 940 | 480 | M20 / M18 | 450 | 450 | 1.32 | 280 | 260 | 1.1 | 20/18 | 508.7/489.9 | 313.7/301.8 |

| 170 | 250 | 513.1/494.6 | 316.3/304.5 | |||||||||||||

| 180 | 260 | 517.5/499.3 | 318.9/307.2 | |||||||||||||

| 2500 | 170 | 250 | 30 | 1670 | 1070 | 480 | M20 / M18 | 500 | 500 | 1.47 | 315 | 280 | 1.18 | 20/18 | 631.1/607.2 | 387.7/372.2 |

| 180 | 260 | 636/612.4 | 390.5/375.4 | |||||||||||||

| 190 | 270 | 641/617.6 | 393.2/378.3 | |||||||||||||

Remarks: The inner hole of the agitator can be made according to user requirements, and the height of the hub is generally consistent with the inner hole.