Home

|About Us

|Product center

|company culture

|News

|Contact Us

|Helical-Coupling

|

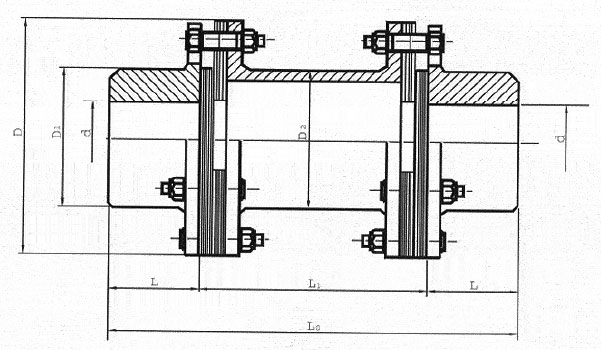

JZMJ diaphragm coupling for heavy machinery (JB/ZQ4717-98)

●The diaphragm coupling is composed of several groups of diaphragms (stainless steel thin plate) which are alternately connected with the two halves of the coupling with bolts. Each group of diaphragms is made up of several pieces. The diaphragms are divided into connecting rod type and different The shape of the whole piece.

●The diaphragm coupling compensates for the relative displacement of the two shafts connected by the elastic deformation of the diaphragm. It is a high-performance flexible coupling with metal elastic elements. It does not require lubrication, has a compact structure, high strength and long service life. , No rotation gap, not affected by temperature and oil pollution, with acid resistance, alkali resistance, and corrosion resistance. It is suitable for high temperature, high speed, and corrosive medium shafting. It is widely used in shafting of various mechanical devices. Transmission, such as water pumps (especially high-power, chemical pumps), fans, compressors, hydraulic machinery, petroleum machinery, printing machinery, textile machinery, chemical machinery, mining machinery, metallurgical machinery, aviation (helicopters), high-speed naval power The transmission system, after being dynamically balanced, is commonly used in high-speed transmission shaft systems.

● JZMJ type diaphragm coupling for heavy machinery has high mechanical strength, large carrying capacity, light weight, small structure size, high transmission efficiency and transmission accuracy, good reliability, convenient assembly and disassembly, and has no relative sliding, no need Lubrication, long service life, no noise, acid, alkali, corrosion resistance, etc., can be used in high temperature, low temperature, oil, water, and corrosive media.Suitable for medium, high speed and large torque shaft transmission.As well as the shaft transmission of various mechanical devices with little change in load, it is extremely versatile.

● Use and maintenance

1. Before installation, clean the end faces of the two shafts and check the fit of the key grooves on the end faces;

2. After the diaphragm coupling is installed, all screws must be checked for normal operation in one shift. If they are found to be loose, they must be tightened. Repeat this for several shifts to ensure that they will not be loosened;

3. In order to prevent the fretting of the diaphragm during high-speed operation, causing microcracks and damage to the bolt holes of the diaphragm, solid lubricants such as molybdenum disulfide can be applied between the diaphragms or the surface of the diaphragm can be coated with anti-friction Layer processing

4. Long-term overload use and operation accidents should be avoided;

5. During work and operation, check whether the diaphragm coupling is abnormal, and repair it if any abnormality occurs;

6. Appropriate protective measures must be taken at various sites where personal and equipment accidents may be caused by the operating diaphragm coupling.