Home

|About Us

|Product center

|company culture

|News

|Contact Us

|Helical-Coupling

|

The company produces nearly 30 types of agitators, including more than 140 kinds of agitators, from the most common (including the existing HB5 standard, SB90 standard various agitators) to a variety of complex shapes or special purpose agitators.It can be manufactured according to the H/T2123-91 standard of various specifications and size series, or according to the user's production process requirements, design and manufacture various special requirements, special specifications or special purpose agitators.

Marking method of agitator model:

|

|

| Material code | |

| Agitator shaft bore | |

| The outer diameter of the stirrer, | |

| Stirrer type code |

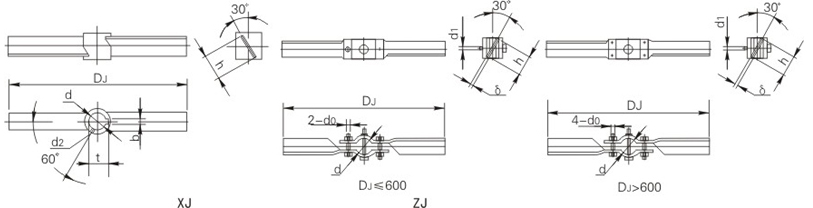

Inclined blade paddle agitator

Oblique blade integral paddle type XJ, oblique blade detachable paddle type ZJ

The blades of this agitator can have an inclination angle of 24°, 45° or 60°, with axial splitting and radial splitting. The flow pattern is more complicated than the straight blade type, and the discharge energy is higher than that of the straight blade. The overall effect is better, and it is applicable The process is the same, so the application frequency is higher than that of the straight blade type, and the operating conditions are the same as those of the straight blade type.

Main dimensions of oblique blade paddle agitator

| DJ | d | h | d1 | Bolt do | Pin shaft φ | d2 | b | t | N/n is not greater than | δ | weight |

| Stainless steel, carbon steel | |||||||||||

| 250 | 25 | 35 | 50 | M10 | 6 | M6 | 8 | 28.3 | 0.0035 | 3/4 | 0.67/0.69 |

| 280 | 30 | 35 | 60 | 8 | 33.3 | 0.005 | 4/6 | 0.83/0.84 | |||

| 320 | 30 | 40 | 60 | 8 | 33.3 | 0.005 | 4/6 | 0.9/0.11 | |||

| 350 | 30 | 40 | 70 | M12 | 8 | M8 | 8 | 33.3 | 0.006 | 6/8 | 1.1/1.38 |

| 35 | 10 | 38.3 | |||||||||

| 400 | 35 | 75 | 10 | 38.3 | 0.01 | 8/10 | 1.55/1.86 | ||||

| 40 | 12 | 43.3 | 1.56/1.88 | ||||||||

| 450 | 40 | 50 | 80 | 10 | 12 | 43.3 | 0.015 | 10/10 | 2.53/2.98 | ||

| 45 | 14 | 48.8 | |||||||||

| 500 | 40 | 50 | 80 | M12 | 10 12 |

12 | 43.3 | 0.015 | 10/10 | 2.53/2.98 | |

| 45 | 14 | 48.8 | 2.72/2.98 | ||||||||

| 550 | 40 | 80 | 12 | 43.3 | 2.86/2.98 | ||||||

| 45 | 14 | 48.8 | 2.96/2.98 | ||||||||

| 600 | 45 | 60 | 90 | 14 | 48.8 | 0.026 | 10/12 | 3.7/4.36 | |||

| 55 | 16 | 593.3 | |||||||||

| 700 | 50 | 70 | 100 | M10 | 14 | 53.8 | 0.04 | 12/14 | 6.14/6.89 | ||

| 60 | 18 | 64.4 | |||||||||

| 850 | 55 | 90 | 110 | 16 | 59.3 | 0.053 | 12/14 | 9.13/10.43 | |||

| 70 | 16 | 20 | 74.9 | ||||||||

| 950 | 65 | 110 | 12 | 16 | 29.3 | 9.83/11.52 | |||||

| 70 | 16 | 20 | 74.9 | ||||||||

| 1100 | 60 | 110 | 120 | M16 | 12 | 18 | 64.4 | 0.07 | 12/14 | 13.58/15.85 | |

| 75 | 16 | 20 | 79.9 | ||||||||

| 1200 | 70 | 120 | 130 | 20 | 74.9 | 0.1 | 14/16 | 18.81/21.27 | |||

| 80 | 22 | 85.4 | 18.95/21.35 | ||||||||

| 1400 | 75 | 140 | 130 | 20 | 79.9 | 0.12 | 14/16 | 24.93/28.23 | |||

| 80 | 22 | 85.4 | 25.09/28.41 | ||||||||

| 1500 | 80 | 150 | 140 | M20 | 20 | M12 | 22 | 85.4 | 0.23 | 14/16 | 30.19/34.5 |

| 85 | 22 | 90.4 | |||||||||

| 1700 |

85 |

180 | 150 | 22 | 90.4 | 0.27 | 14/16 | 50.93/58.5 | |||

| 90 | 25 | 95.4 | |||||||||

| 1800 | 90 | 180 | 160 | 25 | 95.4 | 0.38 | 16/18 | 65.24/73.4 | |||

| 100 | 28 | 106.4 | |||||||||

| 2000 | 95 | 200 | 160 | M16 | 25 | 99.4 | 0.38 | 16/18 | 71.56/80.5 | ||

| 100 | 28 | 106.4 | |||||||||

| 2100 | 95 | 220 | 170 | 25 | 99.4 | 0.5 | 16/18 | 78.13/87.9 | |||

| 110 | 28 | 116.4 | |||||||||

| 2300 | 100 | 240 | 180 | M24 | 24 | 28 | 106.4 | 0.65 | 18/20 | 89.64/99.6 | |

| 120 | 32 | 127.4 | |||||||||

| 2500 | 110 | 250 | 190 | 28 | 116.4 | 0.83 | 18/20 | 104.22/115.8 | |||

| 130 | 32 | 137.4 | |||||||||

| 2800 | 120 | 280 | 200 | M24 | 24 | M20 | 32 | 127.4 | 1.0 | 20/22 | 142/158 |

| 140 | 36 | 148.4 | |||||||||

| 3150 | 130 | 315 | 210 | M24 | 24 | M20 | 32 | 137.4 | 1.2 | 20/22 | 178/198 |

| 150 | 36 | 158.4 | |||||||||

| 3550 | 140 | 355 | 220 | M24 | 24 | M20 | 36 | 148.4 | 1.5 | 20/22 | 224/249 |

| 160 | 40 | 169.4 | |||||||||

Remarks: The inner hole of the agitator can be made according to user requirements, and the height of the hub is generally consistent with the inner hole.