Product Description

GCLD gear coupling Drum toothed coupling

Description:

GCLD series of drum gear coupling, especially suitable for low speed and heavy load conditions, such as metallurgy, mining, lifting and transportation industries, also suitable for petroleum, chemical, general machinery and other machinery shafting transmission.Characteristics of drum gear coupling (compared with straight gear coupling, it has the following characteristics).

Parameters:

Norminal Torque: 0.4kN. M – 4500kN. M

Allowed Rotation Speed: 4000rpm -460rpm

Connection: Keyway & Shaft hole

Shaft Hole Diameter: 16mm – 1040mm

Shaft Hole Length (Y): 42mm – 1100mm

Advantages:

1. The bearing capacity is strong.

2. Large amount of angular displacement compensation

3. The drum shaped tooth surface improves the contact conditions of the inner and outer teeth, avoids the disadvantages of edge extrusion and stress concentration at the straight tooth end under the condition of angular displacement, improves the friction and wear condition of the tooth surface, reduces the noise, and has a long maintenance cycle;

4. The tooth end of the outer tooth sleeve is in the shape of a horn, which makes the assembly and disassembly of the inner and outer teeth very convenient.

5. The transmission efficiency is as high as 99.7%.

Packing & Delivery:

Applications:

Metallurgy, mining, lifting and transportation industries, petroleum, chemical, general machinery and other heavy machinery shaft drive.

About us:

HangZhou CHINAMFG machinery technology Co., Ltd is an industry transmission solutions manufacuturer and service provider.

We offer 1 stop solution for power transmission products for different factories, such as chemicals, energy, material handling, environmental, extraction, pulp and paper, steel and metal, food and beverage, and construction industries.

We supply: Customised gears, Small gearmotors, Industrial gearboxes, Motors, Brand product sourcing.

Our industrial Gear, Gearbox, gearmotor and motor are sold to more than 30 countries. High quality, good price, in time response and sincere service are our value and promises. We aim at making happy cooperation with our customers, bring them reliable and comfortable service.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Advantages of Using Gear Couplings in Mechanical Systems

Gear couplings offer several advantages that make them a popular choice for connecting shafts in mechanical systems. Some of the key advantages include:

- High Torque Capacity: Gear couplings are designed to handle high torque loads, making them suitable for heavy-duty applications that require efficient power transmission.

- Misalignment Compensation: One of the significant advantages of gear couplings is their ability to accommodate various types of misalignment between the connected shafts, including angular, parallel, and axial misalignments. This flexibility helps reduce stress on the connected equipment and improves overall system performance.

- Shock and Vibration Dampening: The meshing of the gear teeth in a gear coupling provides inherent shock and vibration dampening capabilities. This feature helps protect the connected components from sudden impact loads and reduces wear and tear.

- Compact Design: Gear couplings have a compact design, which allows for easy installation even in tight spaces or limited clearance applications.

- High Reliability: Due to their robust construction and excellent torque transmission capabilities, gear couplings are known for their reliability and durability, ensuring long service life in demanding conditions.

- Easy Maintenance: Gear couplings are relatively easy to maintain. Regular inspection and proper lubrication help ensure smooth operation and extend the coupling’s life span.

- Wide Range of Sizes and Configurations: Gear couplings are available in various sizes and configurations, making it possible to find a suitable coupling for a wide range of applications.

- Suitable for High-Speed Applications: Gear couplings can be designed to handle high rotational speeds, making them suitable for applications where high-speed shaft connections are required.

- Temperature and Environment Tolerance: Gear couplings are often made from materials that can withstand high temperatures and harsh environmental conditions, making them suitable for use in challenging industrial settings.

Overall, gear couplings provide a reliable and efficient means of transmitting power between rotating shafts, particularly in heavy-duty and high-torque applications. Their ability to accommodate misalignment and dampen vibrations helps protect connected equipment and contributes to the smooth operation of mechanical systems.

editor by CX 2024-03-12

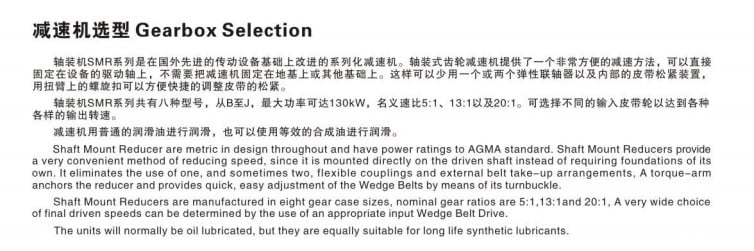

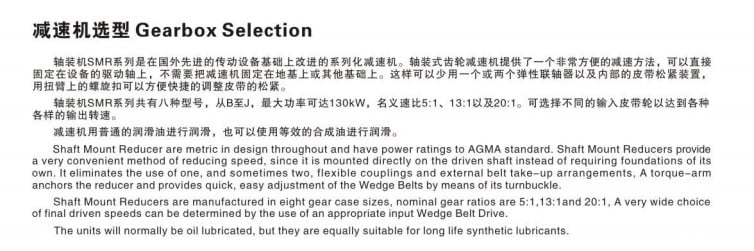

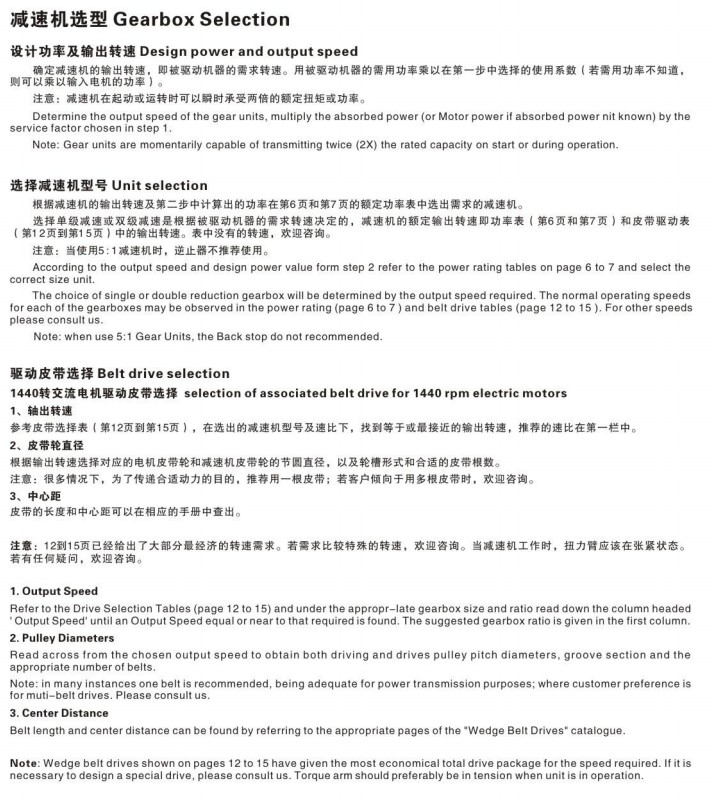

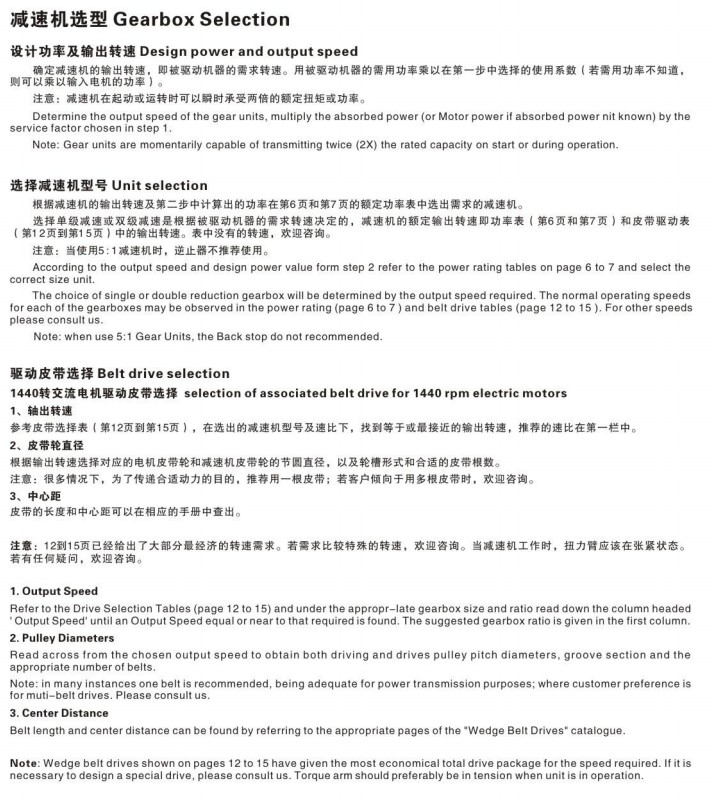

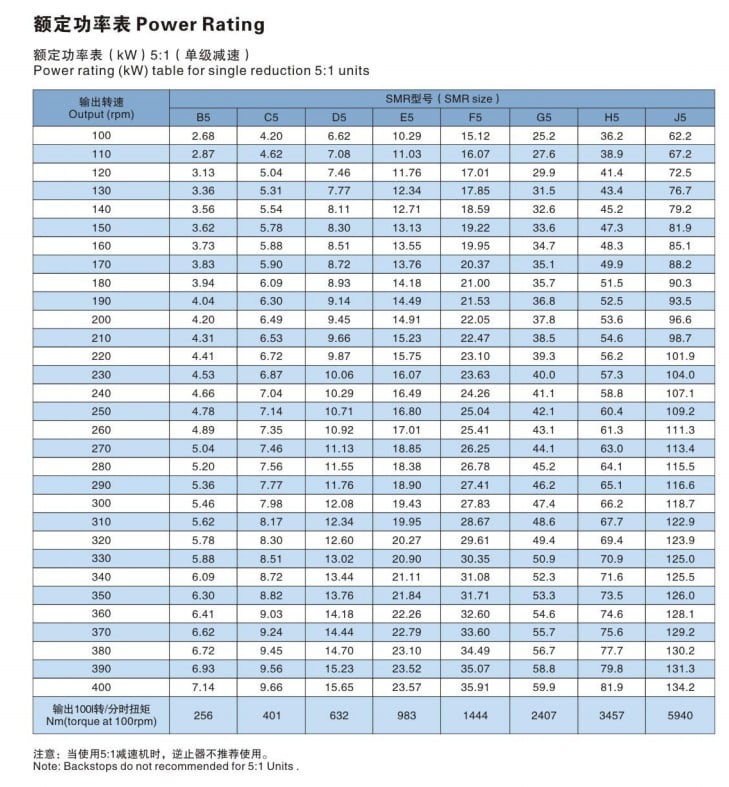

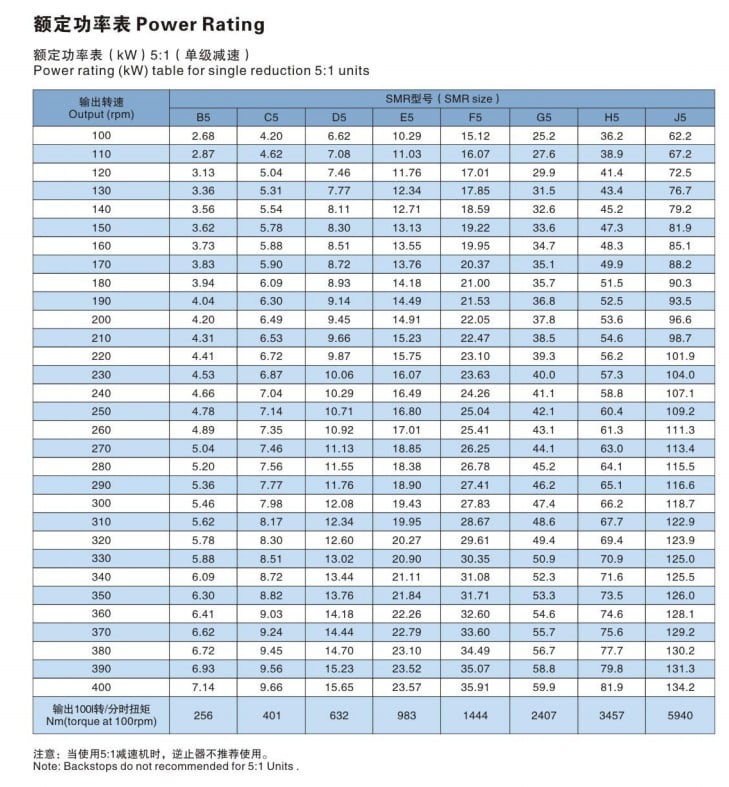

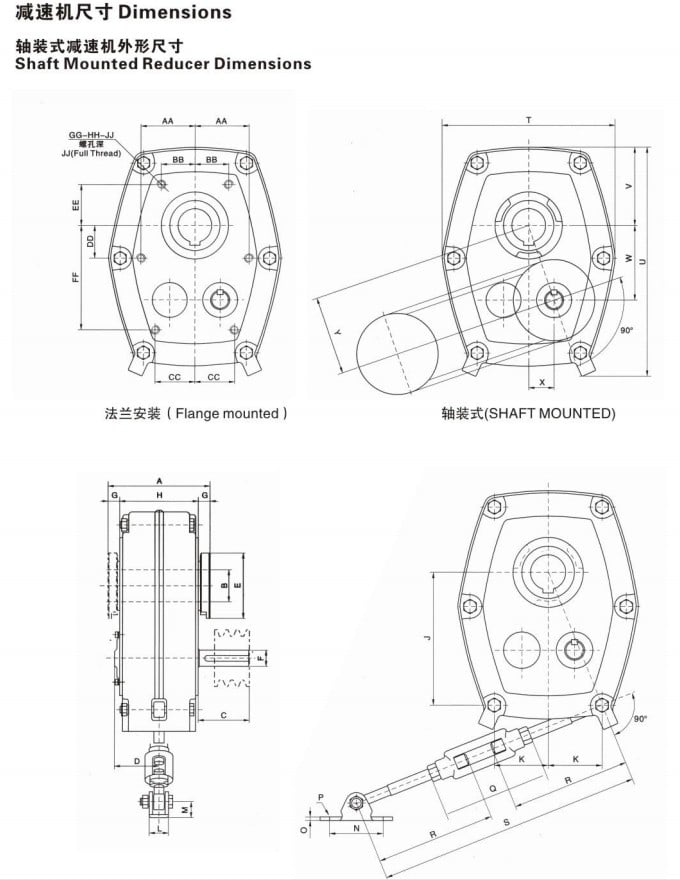

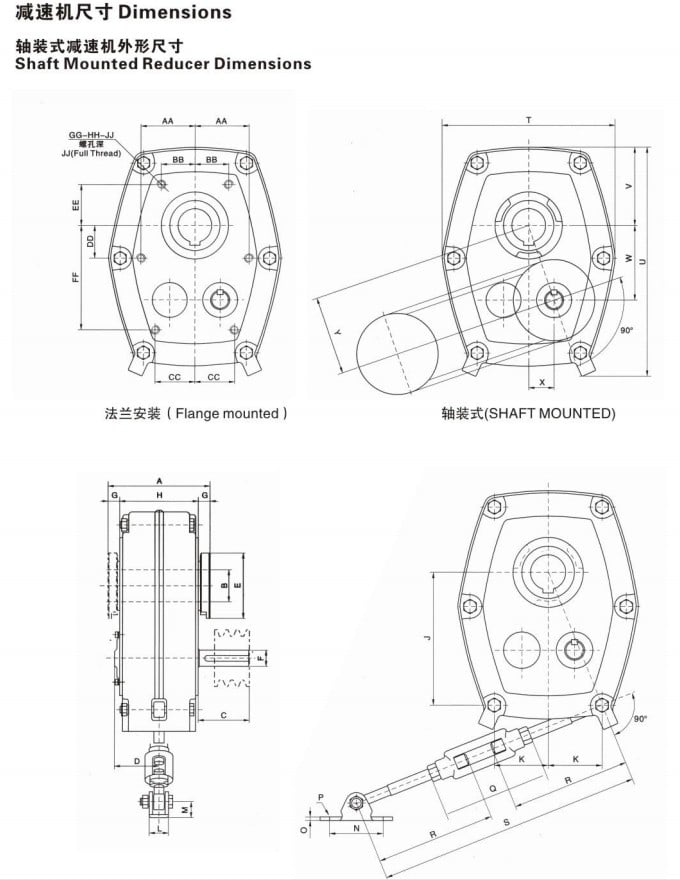

Best China manufacturer & factory SMR electric motor for conveyor belt helical gear speed reducer power transmission shaft mounted gear speed reducer With high quality best price

we have obtained the trust of buyers worldwide. a specialized supplier of a full range of chaEPG aims at playing a leading role in a market which keeps developing new competition strategies with regard to quality, economy and presence. This goal is to be reached by means of the joint support coming from all the company’s departments (Production dept., Technical dept. and Sales dept.) and a highly skilled worldwide distribution network.ins, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Gearing Arrangement:

-

Helical

- Output TorqThe PTO shaft included with all Victory Tractor mowers has a longer extension than the typical PTO Shaft. The added length is necessary because of the far reaching movement of the mowers to the right of the tractor. ue:

-

256-7449N.m

- Input Speed:

-

1400rpm

- Output Speed:

-

100~400RPM

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Color:

-

Blue / Grey / Customer requirement

- Warranty:

-

12 Months

- Product name:

-

Smr Shaft Mounted Reducer

- Certificate:

-

ISO9001

- Ratio:

-

5:13:20

- Heat treatment:

-

Quenching.etc

- Gear material:

-

20CrMnTiH Alloy Steel

- Efficiency:

-

92%~96% (Depends

Supply Ability

- Supply Ability:

- 2000 Set/Sets per Month

Packaging & Delivery

- Packaging Details

- Wooden case per pc + many pcs in big wooden case

- Port

- Shanghai/Ningbo port

Online Customization

SMR electric motor for conveyor belt helical gear speed reducer power transmission shaft mounted gear speed reducer

Product Description

Conveyor & Material Handling

Mining & Quarry

SMR Shafted mounted gearbox for conveyer systems

1) All gears are heat treated and fixed to achieve low noise and high output

EPG is specialized in design, manufacturer and sales of agricultural machinery and farm implements, which has an independent import and export rights. 2) Mounting dimensions are interchangeable with Fenner

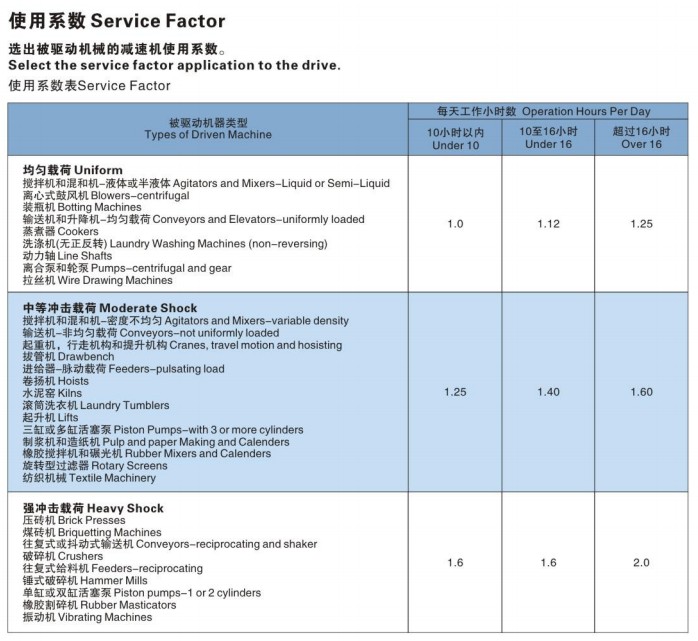

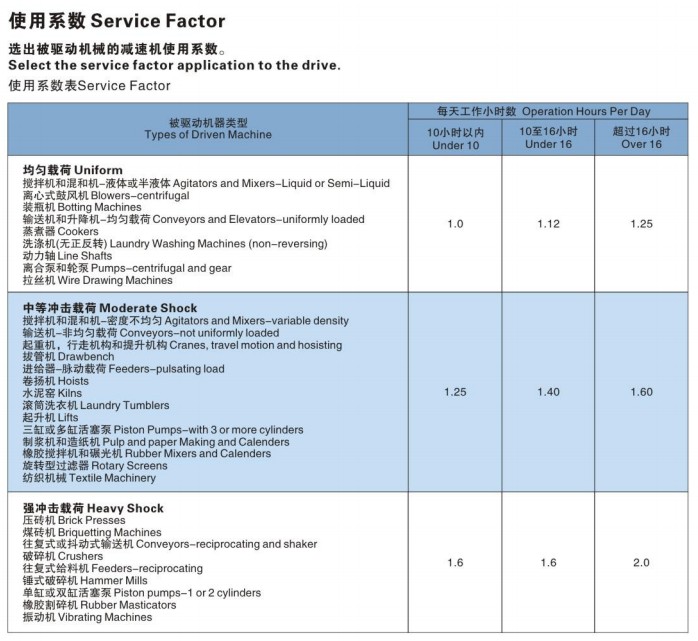

|

SMR Model No. |

Output Shaft Bore [mm] |

Ratio(i) |

|

|

Standard |

Alternative |

||

|

B |

Φ30 |

Φ40 |

5:1 13:1 20:1 |

|

C |

Φ40 |

Φ50 |

|

|

D |

Φ50 |

Φ55 |

|

|

E |

Φ55 |

Φ65 |

|

|

F |

Φ65 |

Φ75 |

|

|

G |

Φ75 |

Φ85 |

|

|

H |

Φ85 |

Φ100 |

|

|

J |

Φ100 |

Φ120 |

|

Company Information

Certifications

Our Services

Packaging & Shipping

FAQ

: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below: