Product Description

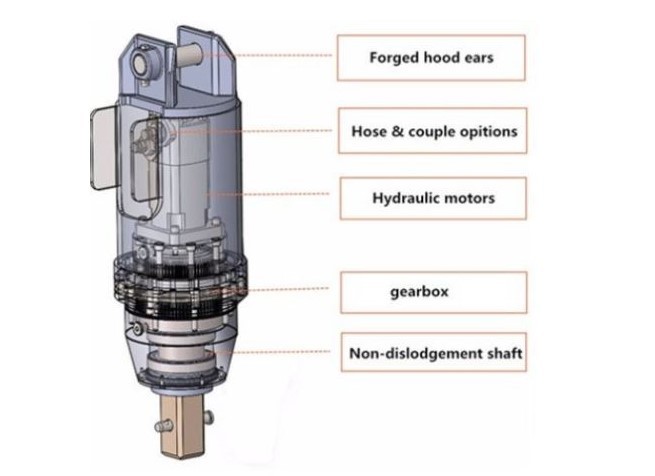

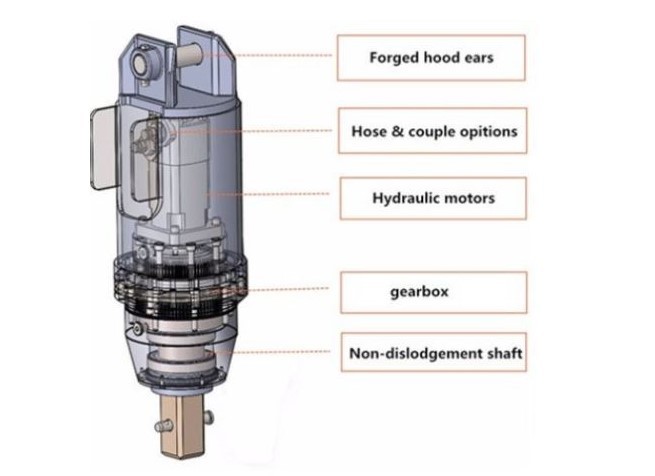

Densen customized hydraulic yox motor hydraulic gear fluid coupling,yot fluid coupling

| Product Name | Densen customized hydraulic yox motor hydraulic gear fluid coupling,yot fluid coupling |

| DN mm | 225~1312mm |

| Rated Torque | 2000~11950000N·m |

| Allowable speed | 1500~3000 RPM |

| Material | 35CrMo/ZG270/45# steel/Aluminum alloy |

| Application | Widely used in metallurgy, mining, engineering and other fields. |

Product show

Company Information

Equipment

Typical case of diaphragm coupling applied to variable frequency speed control equipment

JMB type coupling is applied to HangZhou Oilfield Thermal Power Plant

According to the requirements of HangZhou Electric Power Corporation, HangZhou Oilfield Thermal Power Plant should dynamically adjust the power generation according to the load of the power grid and market demand, and carry out the transformation of the frequency converter and the suction fan. The motor was originally a 1600KW, 730RPM non-frequency variable speed motor matched by HangZhou Motor Factory. The speed control mode after changing the frequency is manual control. Press the button speed to increase 10RPM or drop 10RPM. The coupling is still the original elastic decoupling coupling, and the elastic de-coupling coupling after frequency conversion is frequently damaged, which directly affects the normal power generation.

It is found through analysis that in the process of frequency conversion speed regulation, the pin of the coupling can not bear the inertia of the speed regulation process (the diameter of the fan impeller is 3.3 meters) and is cut off, which has great damage to the motor and the fan.

Later, they switched to the JMB460 double-diaphragm wheel-type coupling of our factory (patent number: ZL.99246247.9). After 1 hour of destructive experiment and more than 1 year of operation test, the equipment is running very well, and there is no Replace the diaphragm. 12 units have been rebuilt and the operation is in good condition.

Other Application Case

Spare parts

Packaging & Shipping

Contact us

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Selection of Gear Couplings for Specific Applications

Choosing the appropriate gear coupling for a specific application involves considering several factors to ensure optimal performance and reliability. Here are the key steps in the selection process:

- Identify Application Requirements: Understand the specific requirements of the application, including the torque and speed requirements, operating conditions, and the amount of angular and axial misalignment expected in the system.

- Calculate Torque and Speed: Determine the required torque and speed ratings for the gear coupling based on the power transmission needs of the application. Consider both peak and continuous torque requirements.

- Consider Misalignment: Evaluate the amount and type of misalignment that the gear coupling needs to accommodate. Different gear coupling designs have varying degrees of misalignment capabilities, so it’s essential to choose one that can handle the expected misalignment in the system.

- Check Space Constraints: Consider the available space for installing the gear coupling. Some applications may have limited space, requiring compact or specially designed couplings to fit properly.

- Assess Environmental Conditions: Determine if the application involves exposure to extreme temperatures, corrosive substances, or other harsh environmental factors. Select a gear coupling made from materials that can withstand the specific environmental conditions.

- Consider Maintenance Requirements: Evaluate the maintenance needs of the gear coupling. Some designs may require more frequent maintenance than others. For applications where regular maintenance is challenging, consider maintenance-free gear coupling options.

- Check Industry Standards and Certifications: Ensure that the selected gear coupling meets relevant industry standards and certifications to guarantee quality and safety.

- Consult with Experts: If needed, seek guidance from coupling manufacturers or engineering experts who can provide valuable insights and recommendations based on their experience and expertise.

By carefully considering these factors and understanding the specific demands of the application, you can select the most suitable gear coupling that will provide reliable and efficient power transmission while minimizing the risk of premature failure or downtime.

editor by CX 2024-04-13

China high quality Flexible Flex Fluid Chain Jaw Flange Gear Rigid Spacer Pin HRC Mh Nm Universal Fenaflex Oldham Spline Clamp Tyre Grid Hydraulic Servo Motor Shaft Coupling gear coupling

Product Description

Flexible flex Fluid Chain Jaw flange Gear Rigid Spacer PIN HRC MH NM universal Fenaflex Oldham spline clamp tyre grid hydraulic servo motor shaft Coupling

Product Description

The function of Shaft coupling:

1. Shafts for connecting separately manufactured units such as motors and generators.

2. If any axis is misaligned.

3. Provides mechanical flexibility.

4. Absorb the transmission of impact load.

5. Prevent overload

We can provide the following couplings.

| Rigid coupling | Flange coupling | Oldham coupling |

| Sleeve or muff coupling | Gear coupling | Bellow coupling |

| Split muff coupling | Flexible coupling | Fluid coupling |

| Clamp or split-muff or compression coupling | Universal coupling | Variable speed coupling |

| Bushed pin-type coupling | Diaphragm coupling | Constant speed coupling |

Company Profile

We are an industrial company specializing in the production of couplings. It has 3 branches: steel casting, forging, and heat treatment. Main products: cross shaft universal coupling, drum gear coupling, non-metallic elastic element coupling, rigid coupling, etc.

The company mainly produces the industry standard JB3241-91 swap JB5513-91 swc. JB3242-93 swz series universal coupling with spider type. It can also design and produce various non-standard universal couplings, other couplings, and mechanical products for users according to special requirements. Currently, the products are mainly sold to major steel companies at home and abroad, the metallurgical steel rolling industry, and leading engine manufacturers, with an annual production capacity of more than 7000 sets.

The company’s quality policy is “quality for survival, variety for development.” In August 2000, the national quality system certification authority audited that its quality assurance system met the requirements of GB/T19002-1994 IDT ISO9002:1994 and obtained the quality system certification certificate with the registration number 0900B5711. It is the first enterprise in the coupling production industry in HangZhou City that passed the ISO9002 quality and constitution certification.

The company pursues the business purpose of “reliable quality, the supremacy of reputation, commitment to business and customer satisfaction” and welcomes customers at home and abroad to choose our products.

At the same time, the company has established long-term cooperative relations with many enterprises and warmly welcomes friends from all walks of life to visit, investigate and negotiate business!

How to use the coupling safely

The coupling is an intermediate connecting part of each motion mechanism, which directly impacts the regular operation of each motion mechanism. Therefore, attention must be paid to:

1. The coupling is not allowed to have more than the specified axis deflection and radial displacement so as not to affect its transmission performance.

2. The bolts of the LINS coupling shall not be loose or damaged.

3. Gear coupling and cross slide coupling shall be lubricated regularly, and lubricating grease shall be added every 2-3 months to avoid severe wear of gear teeth and serious consequences.

4. The tooth width contact length of gear coupling shall not be less than 70%; Its axial displacement shall not be more significant than 5mm

5. The coupling is not allowed to have cracks. If there are cracks, it needs to be replaced (they can be knocked with a small hammer and judged according to the sound).

6. The keys of LINS coupling shall be closely matched and shall not be loosened.

7. The tooth thickness of the gear coupling is worn. When the lifting mechanism exceeds 15% of the original tooth thickness, the operating mechanism exceeds 25%, and the broken tooth is also scrapped.

8. If the elastic ring of the pin coupling and the sealing ring of the gear coupling is damaged or aged, they should be replaced in time.

Certifications

Packaging & Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Limitations and Disadvantages of Using Gear Couplings

While gear couplings offer many advantages, they also have some limitations and disadvantages that should be considered when selecting coupling solutions for specific applications:

- Cost: Gear couplings can be more expensive compared to other types of couplings, especially when precision machining or specialized materials are required. The initial investment might be higher, but the long-term benefits may outweigh the cost.

- Size and Weight: Gear couplings are generally larger and heavier than some other coupling types. This can impact the overall size and weight of the machinery, which may be a concern in applications with limited space or weight restrictions.

- Maintenance: Gear couplings require regular maintenance, including lubrication and periodic inspection to ensure proper functioning. Neglecting maintenance can lead to premature wear and failure.

- Backlash: Like other gear mechanisms, gear couplings may have some inherent backlash due to the clearance between gear teeth. This slight play can affect precision applications where accurate motion transmission is critical.

- Noise and Vibration: Gear couplings can generate more noise and vibration compared to flexible couplings, especially at higher speeds. This can be a concern in applications that require low-noise operation.

- Misalignment Tolerance: While gear couplings can handle moderate misalignment, they may not be as forgiving as flexible couplings in accommodating significant shaft misalignment.

Despite these limitations, gear couplings remain a popular choice for many applications, particularly in heavy-duty industrial settings where they excel in transmitting high torque and handling demanding conditions. Proper selection, installation, and maintenance can help mitigate some of the disadvantages, making gear couplings a reliable choice for power transmission in various industries.

editor by CX 2024-03-10

China manufacturer Flexible Flex Fluid Chain Jaw Flange Gear Rigid Spacer Pin HRC Mh Nm Universal Fenaflex Oldham Spline Clamp Tyre Grid Hydraulic Servo Motor Shaft Coupling gear coupling

Product Description

Flexible flex Fluid Chain Jaw flange Gear Rigid Spacer PIN HRC MH NM universal Fenaflex Oldham spline clamp tyre grid hydraulic servo motor shaft Coupling

Product Description

The function of Shaft coupling:

1. Shafts for connecting separately manufactured units such as motors and generators.

2. If any axis is misaligned.

3. Provides mechanical flexibility.

4. Absorb the transmission of impact load.

5. Prevent overload

We can provide the following couplings.

| Rigid coupling | Flange coupling | Oldham coupling |

| Sleeve or muff coupling | Gear coupling | Bellow coupling |

| Split muff coupling | Flexible coupling | Fluid coupling |

| Clamp or split-muff or compression coupling | Universal coupling | Variable speed coupling |

| Bushed pin-type coupling | Diaphragm coupling | Constant speed coupling |

Company Profile

We are an industrial company specializing in the production of couplings. It has 3 branches: steel casting, forging, and heat treatment. Main products: cross shaft universal coupling, drum gear coupling, non-metallic elastic element coupling, rigid coupling, etc.

The company mainly produces the industry standard JB3241-91 swap JB5513-91 swc. JB3242-93 swz series universal coupling with spider type. It can also design and produce various non-standard universal couplings, other couplings, and mechanical products for users according to special requirements. Currently, the products are mainly sold to major steel companies at home and abroad, the metallurgical steel rolling industry, and leading engine manufacturers, with an annual production capacity of more than 7000 sets.

The company’s quality policy is “quality for survival, variety for development.” In August 2000, the national quality system certification authority audited that its quality assurance system met the requirements of GB/T19002-1994 IDT ISO9002:1994 and obtained the quality system certification certificate with the registration number 0900B5711. It is the first enterprise in the coupling production industry in HangZhou City that passed the ISO9002 quality and constitution certification.

The company pursues the business purpose of “reliable quality, the supremacy of reputation, commitment to business and customer satisfaction” and welcomes customers at home and abroad to choose our products.

At the same time, the company has established long-term cooperative relations with many enterprises and warmly welcomes friends from all walks of life to visit, investigate and negotiate business!

How to use the coupling safely

The coupling is an intermediate connecting part of each motion mechanism, which directly impacts the regular operation of each motion mechanism. Therefore, attention must be paid to:

1. The coupling is not allowed to have more than the specified axis deflection and radial displacement so as not to affect its transmission performance.

2. The bolts of the LINS coupling shall not be loose or damaged.

3. Gear coupling and cross slide coupling shall be lubricated regularly, and lubricating grease shall be added every 2-3 months to avoid severe wear of gear teeth and serious consequences.

4. The tooth width contact length of gear coupling shall not be less than 70%; Its axial displacement shall not be more significant than 5mm

5. The coupling is not allowed to have cracks. If there are cracks, it needs to be replaced (they can be knocked with a small hammer and judged according to the sound).

6. The keys of LINS coupling shall be closely matched and shall not be loosened.

7. The tooth thickness of the gear coupling is worn. When the lifting mechanism exceeds 15% of the original tooth thickness, the operating mechanism exceeds 25%, and the broken tooth is also scrapped.

8. If the elastic ring of the pin coupling and the sealing ring of the gear coupling is damaged or aged, they should be replaced in time.

Certifications

Packaging & Shipping

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Handling Misalignment with Gear Couplings

Gear couplings are designed to accommodate certain degrees of misalignment between shafts, making them suitable for applications where some flexibility is required. They can handle three main types of misalignment:

- Angular Misalignment: This type of misalignment occurs when the axes of the two connected shafts are not parallel but intersect at a small angle. Gear couplings can handle a moderate amount of angular misalignment, typically up to a few degrees, without sacrificing performance.

- Parallel Misalignment: Parallel misalignment refers to a situation where the two connected shafts are offset in parallel but remain parallel to each other. Gear couplings can accommodate a certain amount of parallel misalignment, but it is generally limited to a fraction of the coupling’s overall length.

- Axial Misalignment: Axial misalignment happens when the two shafts are offset along the axis of rotation. Gear couplings can handle limited axial misalignment, but it is essential to ensure that the coupling’s end float or end-play is correctly set to prevent axial loading on connected equipment.

It is important to note that while gear couplings can handle some degree of misalignment, excessive misalignment can lead to premature wear and failure. Regular maintenance and proper installation are crucial to ensuring that gear couplings perform optimally and have a longer service life.

editor by CX 2024-02-26

China factory Flexible Flex Fluid Chain Jaw Flange Gear Rigid Spacer Pin HRC Mh Nm Universal Fenaflex Oldham Spline Clamp Tyre Grid Hydraulic Servo Motor Shaft Coupling gear coupling

Product Description

Flexible flex Fluid Chain Jaw flange Gear Rigid Spacer PIN HRC MH NM universal Fenaflex Oldham spline clamp tyre grid hydraulic servo motor shaft Coupling

Product Description

The function of Shaft coupling:

1. Shafts for connecting separately manufactured units such as motors and generators.

2. If any axis is misaligned.

3. Provides mechanical flexibility.

4. Absorb the transmission of impact load.

5. Prevent overload

We can provide the following couplings.

| Rigid coupling | Flange coupling | Oldham coupling |

| Sleeve or muff coupling | Gear coupling | Bellow coupling |

| Split muff coupling | Flexible coupling | Fluid coupling |

| Clamp or split-muff or compression coupling | Universal coupling | Variable speed coupling |

| Bushed pin-type coupling | Diaphragm coupling | Constant speed coupling |

Company Profile

We are an industrial company specializing in the production of couplings. It has 3 branches: steel casting, forging, and heat treatment. Main products: cross shaft universal coupling, drum gear coupling, non-metallic elastic element coupling, rigid coupling, etc.

The company mainly produces the industry standard JB3241-91 swap JB5513-91 swc. JB3242-93 swz series universal coupling with spider type. It can also design and produce various non-standard universal couplings, other couplings, and mechanical products for users according to special requirements. Currently, the products are mainly sold to major steel companies at home and abroad, the metallurgical steel rolling industry, and leading engine manufacturers, with an annual production capacity of more than 7000 sets.

The company’s quality policy is “quality for survival, variety for development.” In August 2000, the national quality system certification authority audited that its quality assurance system met the requirements of GB/T19002-1994 IDT ISO9002:1994 and obtained the quality system certification certificate with the registration number 0900B5711. It is the first enterprise in the coupling production industry in HangZhou City that passed the ISO9002 quality and constitution certification.

The company pursues the business purpose of “reliable quality, the supremacy of reputation, commitment to business and customer satisfaction” and welcomes customers at home and abroad to choose our products.

At the same time, the company has established long-term cooperative relations with many enterprises and warmly welcomes friends from all walks of life to visit, investigate and negotiate business!

How to use the coupling safely

The coupling is an intermediate connecting part of each motion mechanism, which directly impacts the regular operation of each motion mechanism. Therefore, attention must be paid to:

1. The coupling is not allowed to have more than the specified axis deflection and radial displacement so as not to affect its transmission performance.

2. The bolts of the LINS coupling shall not be loose or damaged.

3. Gear coupling and cross slide coupling shall be lubricated regularly, and lubricating grease shall be added every 2-3 months to avoid severe wear of gear teeth and serious consequences.

4. The tooth width contact length of gear coupling shall not be less than 70%; Its axial displacement shall not be more significant than 5mm

5. The coupling is not allowed to have cracks. If there are cracks, it needs to be replaced (they can be knocked with a small hammer and judged according to the sound).

6. The keys of LINS coupling shall be closely matched and shall not be loosened.

7. The tooth thickness of the gear coupling is worn. When the lifting mechanism exceeds 15% of the original tooth thickness, the operating mechanism exceeds 25%, and the broken tooth is also scrapped.

8. If the elastic ring of the pin coupling and the sealing ring of the gear coupling is damaged or aged, they should be replaced in time.

Certifications

Packaging & Shipping

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Materials Used in Manufacturing Gear Couplings

Gear couplings are designed to transmit torque between shafts while accommodating misalignment. To ensure the durability and reliability of gear couplings, manufacturers use a variety of materials, each with its specific properties. Commonly used materials in manufacturing gear couplings include:

- Steel: Steel is the most widely used material for gear couplings. It offers excellent strength, durability, and resistance to wear and fatigue. Steel gear couplings are suitable for a wide range of applications, including heavy-duty industrial machinery.

- Stainless Steel: Stainless steel is chosen for gear couplings that require resistance to corrosion and high-temperature environments. Stainless steel couplings are commonly used in food processing, pharmaceutical, and chemical industries.

- Alloy Steel: Alloy steel is utilized to enhance specific properties, such as increased strength and improved performance under high loads and extreme conditions. Alloy steel gear couplings are ideal for demanding applications in heavy industries.

- Cast Iron: Cast iron is known for its excellent machinability and good resistance to wear. Cast iron gear couplings are suitable for low to moderate torque applications and can be cost-effective in certain scenarios.

- Non-Metallic Materials: In some cases, non-metallic materials like nylon or urethane may be used for specific gear coupling applications, especially in situations where electrical isolation or chemical resistance is required.

The choice of material depends on the application’s demands, including the torque, speed, environmental conditions, and budget considerations. Gear coupling manufacturers carefully select materials that will provide optimal performance and longevity while meeting the specific requirements of the intended application.

editor by CX 2024-02-08

China factory Flexible Flex Fluid Chain Jaw Flange Gear Rigid Spacer Pin HRC Mh Nm Universal Fenaflex Oldham Spline Clamp Tyre Grid Hydraulic Servo Motor Shaft Coupling gear coupling

Product Description

Flexible flex Fluid Chain Jaw flange Gear Rigid Spacer PIN HRC MH NM universal Fenaflex Oldham spline clamp tyre grid hydraulic servo motor shaft Coupling

Product Description

The function of Shaft coupling:

1. Shafts for connecting separately manufactured units such as motors and generators.

2. If any axis is misaligned.

3. Provides mechanical flexibility.

4. Absorb the transmission of impact load.

5. Prevent overload

We can provide the following couplings.

| Rigid coupling | Flange coupling | Oldham coupling |

| Sleeve or muff coupling | Gear coupling | Bellow coupling |

| Split muff coupling | Flexible coupling | Fluid coupling |

| Clamp or split-muff or compression coupling | Universal coupling | Variable speed coupling |

| Bushed pin-type coupling | Diaphragm coupling | Constant speed coupling |

Company Profile

We are an industrial company specializing in the production of couplings. It has 3 branches: steel casting, forging, and heat treatment. Main products: cross shaft universal coupling, drum gear coupling, non-metallic elastic element coupling, rigid coupling, etc.

The company mainly produces the industry standard JB3241-91 swap JB5513-91 swc. JB3242-93 swz series universal coupling with spider type. It can also design and produce various non-standard universal couplings, other couplings, and mechanical products for users according to special requirements. Currently, the products are mainly sold to major steel companies at home and abroad, the metallurgical steel rolling industry, and leading engine manufacturers, with an annual production capacity of more than 7000 sets.

The company’s quality policy is “quality for survival, variety for development.” In August 2000, the national quality system certification authority audited that its quality assurance system met the requirements of GB/T19002-1994 IDT ISO9002:1994 and obtained the quality system certification certificate with the registration number 0900B5711. It is the first enterprise in the coupling production industry in HangZhou City that passed the ISO9002 quality and constitution certification.

The company pursues the business purpose of “reliable quality, the supremacy of reputation, commitment to business and customer satisfaction” and welcomes customers at home and abroad to choose our products.

At the same time, the company has established long-term cooperative relations with many enterprises and warmly welcomes friends from all walks of life to visit, investigate and negotiate business!

How to use the coupling safely

The coupling is an intermediate connecting part of each motion mechanism, which directly impacts the regular operation of each motion mechanism. Therefore, attention must be paid to:

1. The coupling is not allowed to have more than the specified axis deflection and radial displacement so as not to affect its transmission performance.

2. The bolts of the LINS coupling shall not be loose or damaged.

3. Gear coupling and cross slide coupling shall be lubricated regularly, and lubricating grease shall be added every 2-3 months to avoid severe wear of gear teeth and serious consequences.

4. The tooth width contact length of gear coupling shall not be less than 70%; Its axial displacement shall not be more significant than 5mm

5. The coupling is not allowed to have cracks. If there are cracks, it needs to be replaced (they can be knocked with a small hammer and judged according to the sound).

6. The keys of LINS coupling shall be closely matched and shall not be loosened.

7. The tooth thickness of the gear coupling is worn. When the lifting mechanism exceeds 15% of the original tooth thickness, the operating mechanism exceeds 25%, and the broken tooth is also scrapped.

8. If the elastic ring of the pin coupling and the sealing ring of the gear coupling is damaged or aged, they should be replaced in time.

Certifications

Packaging & Shipping

How Does a Gear Coupling Protect Connected Equipment from Shock Loads and Vibrations?

Gear couplings are designed to provide excellent protection to connected equipment from shock loads and vibrations, making them ideal for use in demanding and heavy-duty applications. The design and features of gear couplings that contribute to this protection include:

- Flexible and Rigid Elements: Gear couplings consist of two hubs with external gears that mesh together. Between these two hubs, there is a center sleeve with internal gear teeth. The center sleeve acts as a flexible element, while the outer hubs act as rigid elements. This combination allows the gear coupling to transmit torque while absorbing and dampening shock loads and vibrations.

- Misalignment Compensation: Gear couplings can accommodate angular, parallel, and axial misalignment between shafts. When the connected equipment experiences misalignment due to dynamic forces or shock loads, the gear coupling can flex and adjust to these changes, preventing excessive stress on the shafts and equipment.

- High Torsional Stiffness: Gear couplings offer high torsional stiffness, meaning they have minimal angular deflection under load. This stiffness helps maintain precise alignment and reduces the likelihood of damage to the connected equipment caused by misalignment-induced vibrations.

- Load Distribution: The toothed gear design of gear couplings ensures a large surface area of contact between the gears. This spreads the torque evenly across the gear teeth, resulting in a uniform distribution of load and reducing the concentration of stress on specific areas.

- Damping Characteristics: The flexible center sleeve in the gear coupling acts as a damping element that absorbs and dissipates vibrations, further protecting the connected equipment from harmful oscillations.

- High-Speed Balancing: Gear couplings are precisely balanced during manufacturing to minimize vibrations and ensure smooth operation even at high speeds. Proper balancing helps prevent resonances and reduces the impact of shock loads on the connected equipment.

By effectively absorbing and dampening shock loads and vibrations, gear couplings extend the life of the connected equipment and surrounding components, reduce maintenance requirements, and contribute to a more reliable and efficient mechanical system. However, it is essential to select the appropriate size and type of gear coupling based on the specific application and operating conditions to ensure optimal protection and performance.

editor by CX 2023-12-01

China wholesaler Flexible Flex Fluid Chain Jaw Flange Gear Rigid Spacer Pin HRC Mh Nm Universal Fenaflex Oldham Spline Clamp Tyre Grid Hydraulic Servo Motor Shaft Coupling gear coupling

Product Description

Flexible flex Fluid Chain Jaw flange Gear Rigid Spacer PIN HRC MH NM universal Fenaflex Oldham spline clamp tyre grid hydraulic servo motor shaft Coupling

Product Description

The function of Shaft coupling:

1. Shafts for connecting separately manufactured units such as motors and generators.

2. If any axis is misaligned.

3. Provides mechanical flexibility.

4. Absorb the transmission of impact load.

5. Prevent overload

We can provide the following couplings.

| Rigid coupling | Flange coupling | Oldham coupling |

| Sleeve or muff coupling | Gear coupling | Bellow coupling |

| Split muff coupling | Flexible coupling | Fluid coupling |

| Clamp or split-muff or compression coupling | Universal coupling | Variable speed coupling |

| Bushed pin-type coupling | Diaphragm coupling | Constant speed coupling |

Company Profile

We are an industrial company specializing in the production of couplings. It has 3 branches: steel casting, forging, and heat treatment. Main products: cross shaft universal coupling, drum gear coupling, non-metallic elastic element coupling, rigid coupling, etc.

The company mainly produces the industry standard JB3241-91 swap JB5513-91 swc. JB3242-93 swz series universal coupling with spider type. It can also design and produce various non-standard universal couplings, other couplings, and mechanical products for users according to special requirements. Currently, the products are mainly sold to major steel companies at home and abroad, the metallurgical steel rolling industry, and leading engine manufacturers, with an annual production capacity of more than 7000 sets.

The company’s quality policy is “quality for survival, variety for development.” In August 2000, the national quality system certification authority audited that its quality assurance system met the requirements of GB/T19002-1994 IDT ISO9002:1994 and obtained the quality system certification certificate with the registration number 0900B5711. It is the first enterprise in the coupling production industry in HangZhou City that passed the ISO9002 quality and constitution certification.

The company pursues the business purpose of “reliable quality, the supremacy of reputation, commitment to business and customer satisfaction” and welcomes customers at home and abroad to choose our products.

At the same time, the company has established long-term cooperative relations with many enterprises and warmly welcomes friends from all walks of life to visit, investigate and negotiate business!

How to use the coupling safely

The coupling is an intermediate connecting part of each motion mechanism, which directly impacts the regular operation of each motion mechanism. Therefore, attention must be paid to:

1. The coupling is not allowed to have more than the specified axis deflection and radial displacement so as not to affect its transmission performance.

2. The bolts of the LINS coupling shall not be loose or damaged.

3. Gear coupling and cross slide coupling shall be lubricated regularly, and lubricating grease shall be added every 2-3 months to avoid severe wear of gear teeth and serious consequences.

4. The tooth width contact length of gear coupling shall not be less than 70%; Its axial displacement shall not be more significant than 5mm

5. The coupling is not allowed to have cracks. If there are cracks, it needs to be replaced (they can be knocked with a small hammer and judged according to the sound).

6. The keys of LINS coupling shall be closely matched and shall not be loosened.

7. The tooth thickness of the gear coupling is worn. When the lifting mechanism exceeds 15% of the original tooth thickness, the operating mechanism exceeds 25%, and the broken tooth is also scrapped.

8. If the elastic ring of the pin coupling and the sealing ring of the gear coupling is damaged or aged, they should be replaced in time.

Certifications

Packaging & Shipping

Are There Any Safety Considerations When Using Gear Couplings in Rotating Machinery?

Yes, there are several safety considerations to keep in mind when using gear couplings in rotating machinery:

- Guarding: It is essential to provide adequate guarding around gear couplings and other rotating parts to prevent accidental contact with moving components. Proper guarding helps protect personnel from potential entanglement, pinch points, or other hazards.

- Maintenance and Inspection: Regular maintenance and inspection of gear couplings are critical to ensure their safe and reliable operation. This includes checking for signs of wear, lubrication levels, and any abnormalities in the coupling’s performance.

- Lubrication: Proper lubrication of the gear coupling is essential to reduce friction, wear, and heat generation. Follow the manufacturer’s guidelines for lubrication intervals and use the recommended lubricant type.

- Temperature Monitoring: In high-speed or high-temperature applications, it is advisable to monitor the temperature of the gear coupling during operation. Excessive heat can indicate issues with lubrication or alignment that need immediate attention.

- Alignment: Ensure proper alignment of the connected shafts and gear coupling during installation. Misalignment can lead to increased wear, vibration, and premature failure of the coupling.

- Torque and Speed Limitations: Adhere to the specified torque and speed limitations provided by the gear coupling manufacturer. Operating the coupling beyond its rated capacity can result in failures and safety hazards.

- Emergency Shutdown: Machinery equipped with gear couplings should have an accessible and effective emergency shutdown mechanism to quickly stop the equipment in case of emergencies.

- Training: Provide proper training to personnel who work with or around machinery equipped with gear couplings. Training should cover safety protocols, coupling maintenance procedures, and the potential hazards associated with the equipment.

- Replace Damaged Couplings: If a gear coupling shows signs of damage, excessive wear, or malfunction, it should be replaced promptly to prevent potential accidents or equipment breakdowns.

Following these safety considerations can help ensure the safe and efficient operation of rotating machinery equipped with gear couplings. Regular maintenance, adherence to safety guidelines, and proper training contribute to a safer working environment and prolong the service life of gear couplings and the connected equipment.

editor by CX 2023-09-30

Best China manufacturer & factory Planetary in Las Vegas United States Gearbox For Hydraulic Drive Digger In Line Post Hole Digger motor Manure Spreader Plough Rotary tiller Rotavator Lime With high quality best price

In this way, our merchandise have continued to obtain market acceptance and customers fulfillment over the earlier number of years.

Overview

Quick Specifics

- Relevant Industries:

-

Production Plant, Equipment Repair Shops, farms, Retail, put up hole digger Planetary Gearbox

- Place of Origin:Zhejiang, China

- Manufacturer Identify:

-

OEM

- Gearing Arrangement:

-

Planetary

- Output Torque:

-

–

- Input Velocity:

-

–

- Output Velocity:

-

–

Source Capability

- Provide Capacity:

- 10000 Piece/Parts per Thirty day period

Packaging & Shipping and delivery

- Packaging Specifics

- picket scenario

- Port

- Shanghai/Ningbo

-

Direct Time

: -

Quantity(Pieces) one – one thousand >1000 Est. Time(times) 35 To be negotiated

On the internet Customization

Item Description

Planetary Gearbox For Hydraulic Generate Digger In Line

Organization Profie

Specialist IN Generating ALL Varieties OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Equipment Speed REDUCERS, ARALAdvantages of Worm GearsLEL SHAFT HELICAL Equipment REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Gear REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Automobile GEARBOXES, PTO Drive SHAFTS, Unique REDUCER & Related Equipment Elements AND OTHER Relevant Merchandise, SPROCKETS, HYDRAULIC Technique, VACUUM PUMPS, FLUID COUPLING, Equipment RACKS, CHAINS, TIMING PULLEYS, UDL Speed VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Gear PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Reduced BACKLASH WORM REDUCERS AND SO ON. Furthermore, WE CAN Produce Personalized VARIATORS, GEARED MOTORS, Electrical MOTORS AND OTHER HYDRAULIC Merchandise

In accordance TO CUSTOMERS’ DRAWINGS.

Certifications

FAQ

Q: Are you buying and selling business or company ?

A: Our team is composed in 3 factories and 2 overseas income firms.

Q: Do you supply samples ? is it free or extra ?

A: Indeed, we could offer the sample for free of charge demand but do not pay the price of freight.

Q: How lengthy is your shipping time ? What is your phrases of payment ?

A: Generally it is 40-forty five days. The time might fluctuate depending on the solution and the amount of customization. For standard products, the payment is: thirty% T/T in progress ,equilibrium ahead of shippment.

Q: What is the precise MOQ or cost for your product ?

A: As an OEM organization, we can supply and adapt our products to a broad assortment of needs.Therefore, MOQ and value could tremendously vary with measurement, material and further specifications For instance, pricey items or regular goods will normally have a reduce MOQ. You should make contact with us with all relevant information to get the most precise quotation.

If you have one more questOur PTO push shafts permit the person easy routine maintenance. The greasing nipples on normal crosses are positioned beneath angle to empower the user far better access. Simpler accessibility is also possible because of the flexible cone. We listened to the needs of our buyers and put the greasing nipple at extensive-angle PTO’s into the cross bearing. The other novelty, we launched with extensive-angle PTO travel shafts is in line greasing. We wished to additionally simplify the upkeep and increase the lifespan of joints.ion, remember to come to feel totally free to get in touch with us.

Packing & Supply

Why Decide on Us

Also I would like to just take this possibility to give a quick introduction of our Ever-PowOur manufacturing facility has attained the certificate of China’s Farm Equipment Goods High quality Authentication promulgated by the Farm Machinery Products Top quality Authentication Centre of China. er business:

Our company is a renowned maker of agriculture gearbox,worm lessen gearbox, PTO shafts, Sprockets ,rollar chains, bevel gear, pulleys and racks in china.

We have exported numerous items to our customers all more than the world, we have extended-time experience and powerful technologies assistance.

Some of our customer :

Italy: GB GEABOX, SATI, CHIARAVALLI, AMA, Brevini

Germany: SILOKING ,GKN ,KTS

France: Itfran, Sedies, Kuhn

Brazil: AEMCO ,STU

Usa: John Deere , BLOUNT, Weasler, Agco, Omni Gear, WOODS

Canada: JAY-LOR , CANIMEX ,RingBall

……

-> Our Firm with over twelve year’s background and one thousand staff and twenty sales.

-> With more than 100 Million USD income in 2017

-> With progress machinery equipments

-> With massive operate potential and large top quality handle, ISO accredited.

……

you also can verify our internet site to know for much more details, if you need our products catalogue, you should make contact with with us.

|

For far more element, please get in touch with us. |

For much more element, remember to get in touch with us.

Best China manufacturer & factory china in Lubango Angola factory supplier EPG ORBITAL MOTOR OMH 151H-1052 151H-1053 151H-1054 151H-1055 151H-1056 EPG OMH hydraulic motor With high quality best price

Additionally, all our production procedures are in compliance with ISO9002 standards for a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

The PTO shaft is the mechanical device that transfer the power from the tractor to the agricultural implement. The PTO shaft is made of two joints connected by telescopic tubes: one joint connects the outer tube of the PTO shaft with the tractor power take-off , the other joint connects the inner tube of the PTO shaft with the implement. The range of the EPG GROUP PTO shafts includes 9 sizes of different dimensions according to the power to be transferred . The sizes of the EPG GROUP PTO shafts and the power that can be transferred at 540 rpm are : SIZE 1 up to 16HP SIZE 2 up to 21HP SIZE 3 up to 30 HP SIZE 4 up to 35HP SIZE 5 up to 47HP SIZE 6 up to 60HP SIZE 7 up to 70HP SIZE 8 up to 90HP SIZE10 up to 110HP

- After Warranty Service:

-

Video technical support

- Local Service Location:

-

Egypt

- Showroom Location:

-

Egypt

- Type:

-

Precision Worm Gearboxes and Worm-Wheel Sets

parts

- After-sales Service Provided:

-

Video technical support

Supply Ability

- Supply Ability:

- 500000 Piece/Pieces per Year

Packaging & Delivery

- Packaging Details

- Carton or Plywood case

- Port

- NINGBO/SHANGHAI, CHINA

-

Lead Time

: -

Quantity(Bags) 1 – 50 EPG specializing in the manufacture of rotocultivator ploughshares and other non-standardized farm machinery cutting tools.

>50 Est. Time(days) 15 To be negotiated

Online Customization

BMH TECHNICAL DATA

| TYPE | BMH-200 | BMH-250 | BMH-315 | BMH-400 | BMH-500 | |

| Displacement(ml/r) | 203 | 253.7 | 318.9 | 405.9 | 471.1 | |

| Max.Pressure.Drop(Mpa) | cont. | 16 | 16 | 15 | 14 | 12 |

| int. | 19 | 19 | 18 | 17 | 15 | |

| peak. | 22 | 22 | 21 | 20 | 18 | |

| Max.torque(N.m) | cont. | 425 | 530 | 610 | 825 | 720 |

| int. | 510 | 635 | 750 | 900 | 910 | |

| peak. | 590 | 735 | 875 | 1055 | 1090 | |

| Max. Speed (cont.)(r/min) |

365 | 295 | 235 | 180 | 155 | |

| Max.Flow(cont.)(L/mim) | 75 | 75 | 75 | 75 | 75 | |

| Max.Output.Power(cont.)(Kw) | 13.8 | 13.8 | 12.5 | 11.5 | 9.8 | |

| Weight(Kg) | 10.5 | 11 | 11.5 | 12.5 | 13 | |

Intermittent operation the permissible values may occur for max.10% of every minute

Peak load:the permissible values may occur for max.1% of every minute

Best China manufacturer & factory china supplier bms hydraulic motororbit motor seal kitsorbit EPG motor hidrolik With high quality best price

If you are interested in any of our products or would like to discuss a potential order, please feel free to contact us.

Overview

Quick Details

- After Warranty Service:

-

Video technical support

- Local Service Location:

-

Egypt

- Showroom Location:

-

Egypt

- Type:

-

parts

- After-sales Service Provided:

-

Video technical support

Supply Ability

- Supply Ability:

- 500000 Piece/Pieces per Year

Packaging & Delivery

- Packaging Details

- Carton or Plywood case or PALLET

- Port

- NINGBO/SHANGHAI, CHINA

-

Lead Time

: -

Quantity(Bags) 1 – 50 >50 Est. Time(days) 15 To be negotiated Slip Clutch PTO Shaft for Compact Tractor Tillers NEW SLIPCLUTCH PTO SHAFT FOR COMPACT TRACTOR TILLERS ROTO TILLERS BUSHHOG RHINO KINGKUTTER,CARONI,MASCHIO,JOHN DEERE, MOST MODELS three different types of PTO in operation: a non shear, shear pin and slip clutch — the last being the most expensive. Implement end of non shear (r) and shear type (l) Non shear: this is a solid yoke to yoke set up and used with the expectation that certain equipment will not encounter any sudden stops. I figure that the finishing mower does not need a shear set up as the blades will slip to a degree being belt driven and my other mower, the flail mower, is extremely forgiving in its design.

Online Customization

| TYPE | BMR-50 BMRW-50 BMRS-50 |

BMR-80 BMRW-80 BMRS-80 |

BMR-100 BMRW-100 BMRS-100 |

BMR-125 BMRW-125 BMRS-125 |

BMR-160 BMRW-160 BMRS-160 |

BMR-200 BMRW-200 BMRS-200 |

BMR-250 BMRW-250 BMRS-250 |

BMR-315 BMRW-315 BMRS-315 |

BMR-400 BMR EPG is specialized in design, manufacturer and sales of agricultural machinery and farm implements, which has an independent import and export rights. W-400 BMRS-400 |

|

| Displacement(ml/r) | 51.7 | 80.5 | 100.5 | 126.3 | 160.8 | 200.9 | 252.6 | OUR HIGH-END SEGMENT: FINDING THE BEST SOLUTION FOR THE CUSTOMER The high-end segment often requires customized solutions. In these cases, we provide you with in-depth consulting in order to devise a common solution to meet your requirements. Only then do we get down to the actual work.321.5 | 401.9 | |

| Max.Pressure.Drop (Mpa) | cont. | 14 | 14 | 14 | 14 | 14 | 14 | 11 | 9 | 7 |

| int. | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 14 | 11 | 9 | |

| peak. | 20 | 20 | 20 | 20 | 20 | 20 | 16 | 13 | 11 | |

| Max.torque(N.m) | cont. | 93 | 152 | 194 | 237 | 310 | 369 | 380 | 380 | 380 |

| int. | 118 | 189 | 236 | 296 | 378 | 450 | 470 | 470 | 470 | |

| peak. | 135 | 216 | 270 | 338 | 433 | 509 | 540 | 540 | 540 | |

| Max. Speed (cont.)(r/min) |

770 | 745 | 595 | 475 | 370 | 295 | 235 | 185 | 150 | |

| Max.Flow(cont.)(L/mim) | 40 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | |

| Max.Output.Power(cont.)(Kw) | 7 | 10 | 10 | 10 | 10 | 8 | 6 | 5 | 4 | |

| Weight(Kg) | 6.5 | 6.9 | 7 | 7.3 | 7.5 | 8 | 8.5 | 9 | 11 | |