Product Description

Factory OEM coupling barrel-shaped type intermediate shaft motor belt conveyor flange pump crusher Drum gear coupling for steel mill

Gear Couplings

Advantage:

1. Widely used in various mechanical and hydraulic fields

2. Low-cost maintenance

3. Compensation for axial, radial and angular misalignment

4. Convenient axial plugging assembly

5. Installed horizontally and vertically without using any social tools.

6. Excellent mechanical properties

7. No brittlement at low temperature

8. Good slippery and frictional properties

9. Exellent electrical insulation

Application:

1. Printing machinery / Packing machinery / Wood-working machinery etc large-scale mechanical equipment

2. Repair replacement

Company Information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Selection of Gear Couplings for Specific Applications

Choosing the appropriate gear coupling for a specific application involves considering several factors to ensure optimal performance and reliability. Here are the key steps in the selection process:

- Identify Application Requirements: Understand the specific requirements of the application, including the torque and speed requirements, operating conditions, and the amount of angular and axial misalignment expected in the system.

- Calculate Torque and Speed: Determine the required torque and speed ratings for the gear coupling based on the power transmission needs of the application. Consider both peak and continuous torque requirements.

- Consider Misalignment: Evaluate the amount and type of misalignment that the gear coupling needs to accommodate. Different gear coupling designs have varying degrees of misalignment capabilities, so it’s essential to choose one that can handle the expected misalignment in the system.

- Check Space Constraints: Consider the available space for installing the gear coupling. Some applications may have limited space, requiring compact or specially designed couplings to fit properly.

- Assess Environmental Conditions: Determine if the application involves exposure to extreme temperatures, corrosive substances, or other harsh environmental factors. Select a gear coupling made from materials that can withstand the specific environmental conditions.

- Consider Maintenance Requirements: Evaluate the maintenance needs of the gear coupling. Some designs may require more frequent maintenance than others. For applications where regular maintenance is challenging, consider maintenance-free gear coupling options.

- Check Industry Standards and Certifications: Ensure that the selected gear coupling meets relevant industry standards and certifications to guarantee quality and safety.

- Consult with Experts: If needed, seek guidance from coupling manufacturers or engineering experts who can provide valuable insights and recommendations based on their experience and expertise.

By carefully considering these factors and understanding the specific demands of the application, you can select the most suitable gear coupling that will provide reliable and efficient power transmission while minimizing the risk of premature failure or downtime.

editor by CX 2024-04-02

Motor made in China – replacement parts – in Marseille France Generator Pump Gear Coupling for Chain Conveyor with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing facility in China with 5 diverse branches. For much more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

| Identify | B-65 Nylon Sleeve pump Gear Tooth Coupling |

| Material | MC Nylon/PA66/POM/ PU/ UHMW-PE/Teflon/ PVDF/ PPS/PEEK/PSU etc. As your like. |

| Colour | All-natural,White,Black,Inexperienced,Blue,Yellow,as your prerequisite |

| Diameter | 10-500mm,or custom-made |

| Density | 1.2g/cm2 |

| Situation | In stock/Made to buy |

| Price | Factory price tag presented |

| OEM/ODM | Buyers give style or photograph or we generate style according to customers’ demands. |

| Form | Sheet, rod, tube, gear, pulley, information rail, and so on |

Applications:

Mainly used in the mining, metallurgical, cement, chemical compounds, development, building materials,

Electric power, telecommunications, textiles, and transportation departments.

Such as:

1. EPT Belt conveyor, AFC conveyor, chain conveyor, screw conveyor.

2. Pump: Water pump, oil pump, slush pump, etc.

three. Admirer:Draft fan,admirer,boil fan,and many others.

four. Excavator: Bucket excavator, bucket wheel excavators, bucket wheel stacker reclaimer.

5. Crane: Tower crane, gantry crane, bridge crane.

6. Other individuals: Various elevators, coal plough, ball mill, crusher, recreation machine.

seven. Blender equipment, centrifuge, washer, leather-making machine, machine for recreation

park mixer wire drawing machine. Extruder, and dregs crusher of boiler.

8. Plastic feeder, rubber smelling machine, etc.

Workshop

EPT goods

About us

HangZhou HangZhouANG Gear Co., Ltd. With a historical past of a lot more than twenty years, is specialized in creating sprocket, equipment, coupling, taper bush and EPT transmission merchandise.

The organization was started in 1993 and at the moment employs far more than one hundred folks. It addresses an region of eighteen, 000 square meters, with much more than 250 sets of a variety of kinds of metallic processing gear, such as 90 sets of CNC equipment.

We undertake the pursuing normal to produce our items: ISO 606 ANSIB 29.1 DIN 1801 GB 124-97.

Our products are exported to far more than 60 nations around the world and regions, such as U. S. A, Japan, Germany, Italy, Argentina, South Africa.

Sprocket is our primary things for exporting. We can provide you various kinds of sprocket, Pitch dimensions from 1/4″ to 4″ and enamel No. From 8 to a hundred and fifty.

We always provide our buyers aggressive price, superb top quality and prompt shipping. We constantly contemplate customer’ S requirements first. Our goal is: “Customer’ S pleasure is our pursuit”.

We sincerely hope to set up prolonged-time period company relations with every personalized on the basis mutual positive aspects and friendship.

The use of first equipment manufacturer’s (OEM) part numbers or emblems , e.g. CASE® and John Deere® are for reference purposes only and for indicating item use and compatibility. Our organization and the detailed substitute parts contained herein are not sponsored, accepted, or created by the OEM.

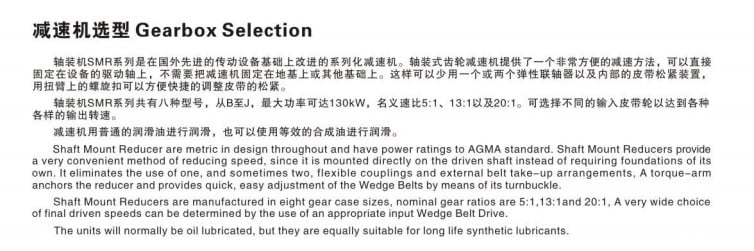

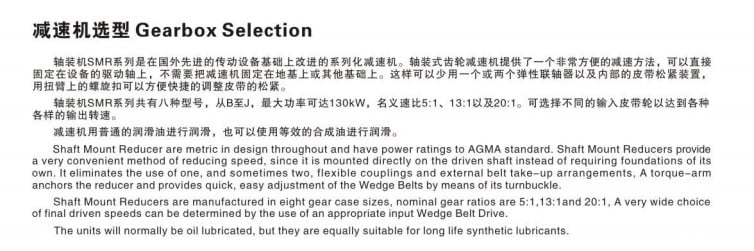

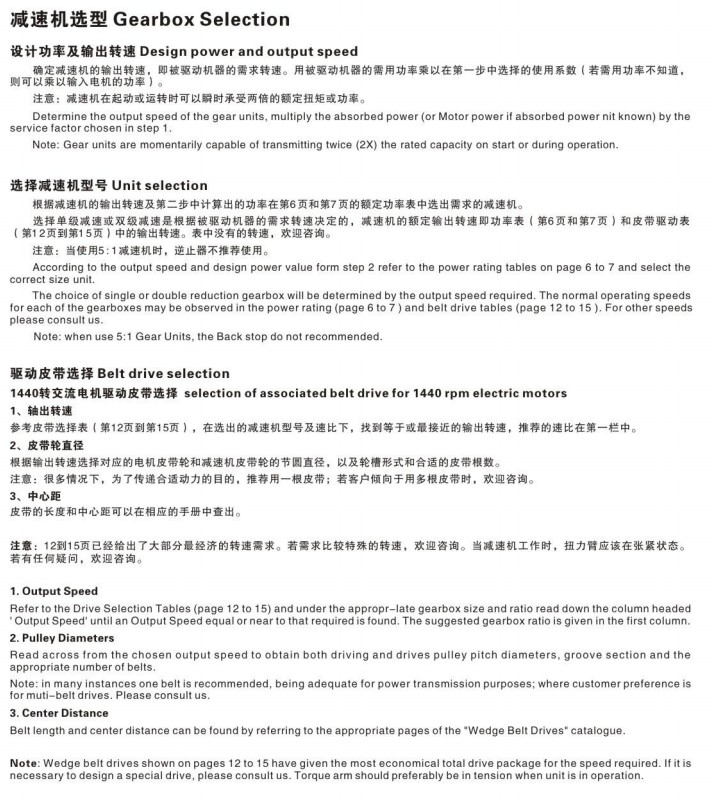

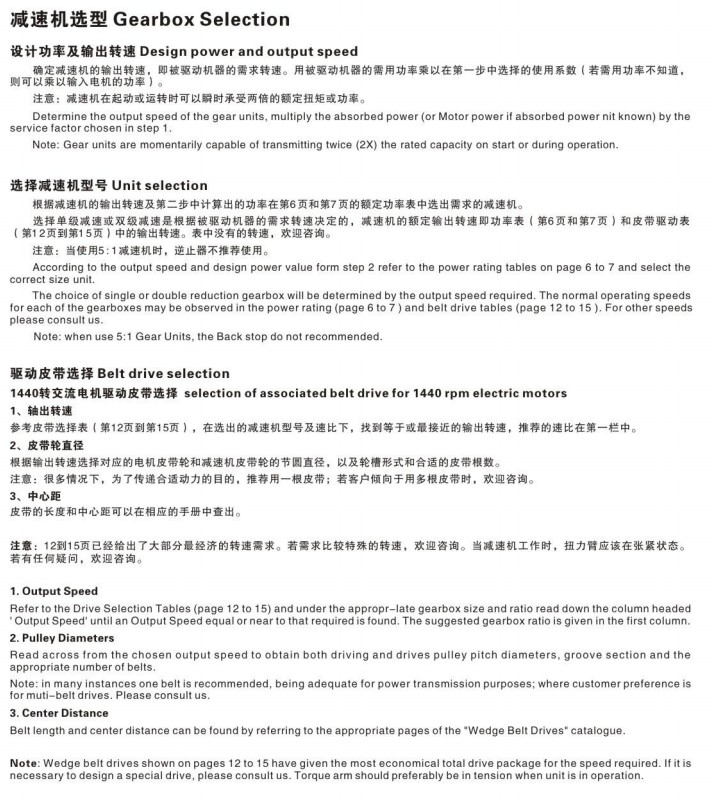

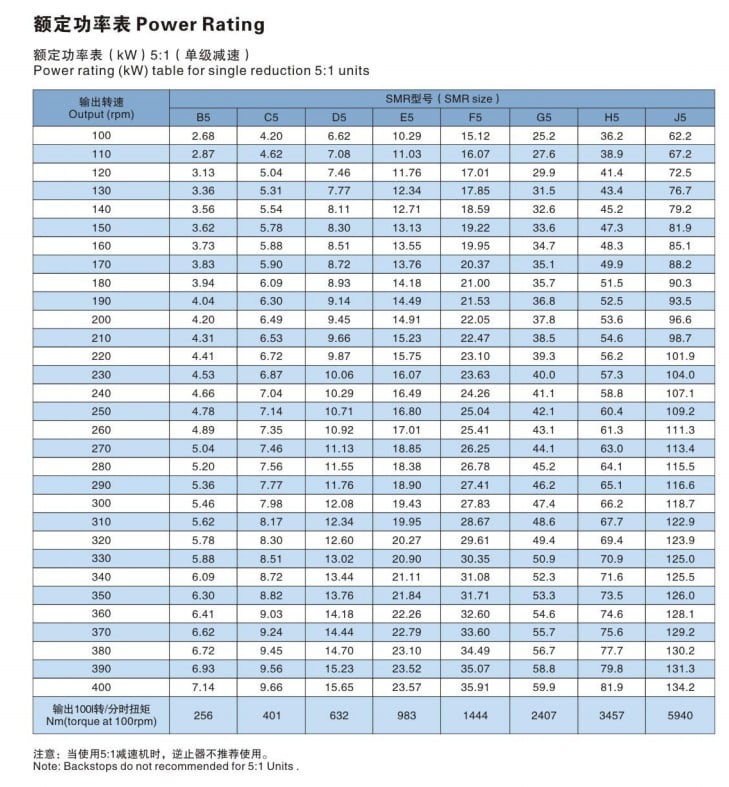

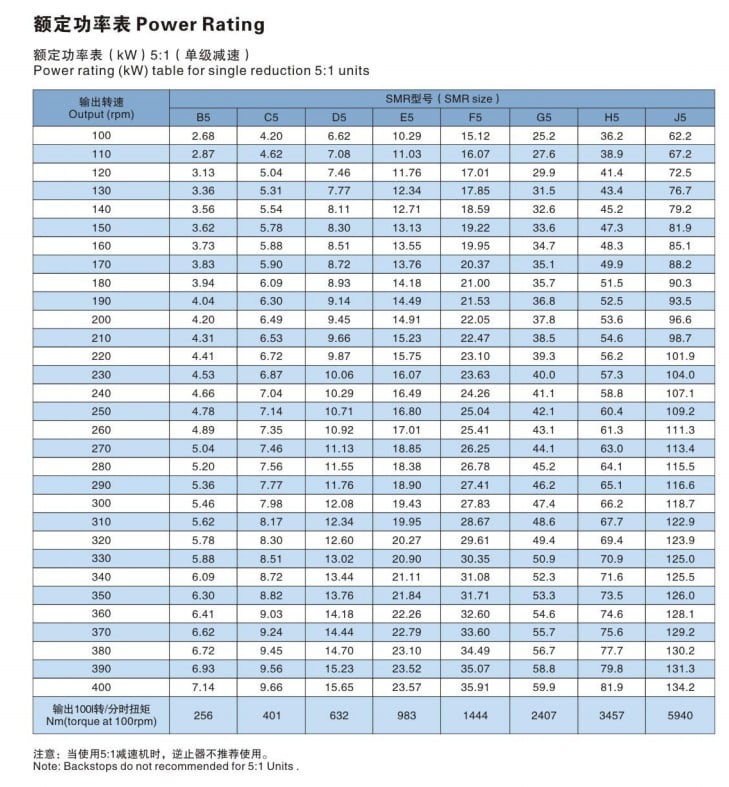

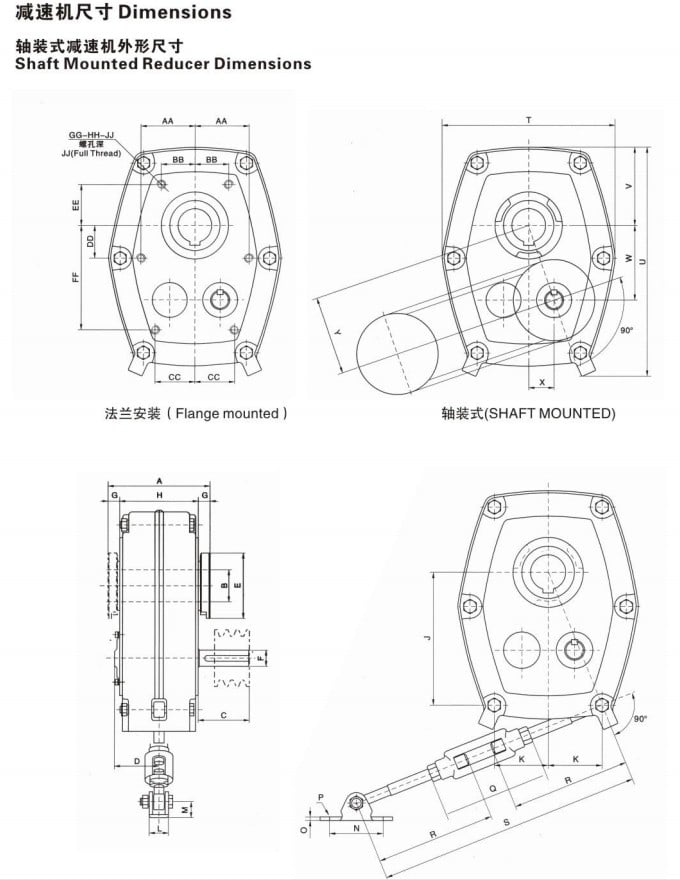

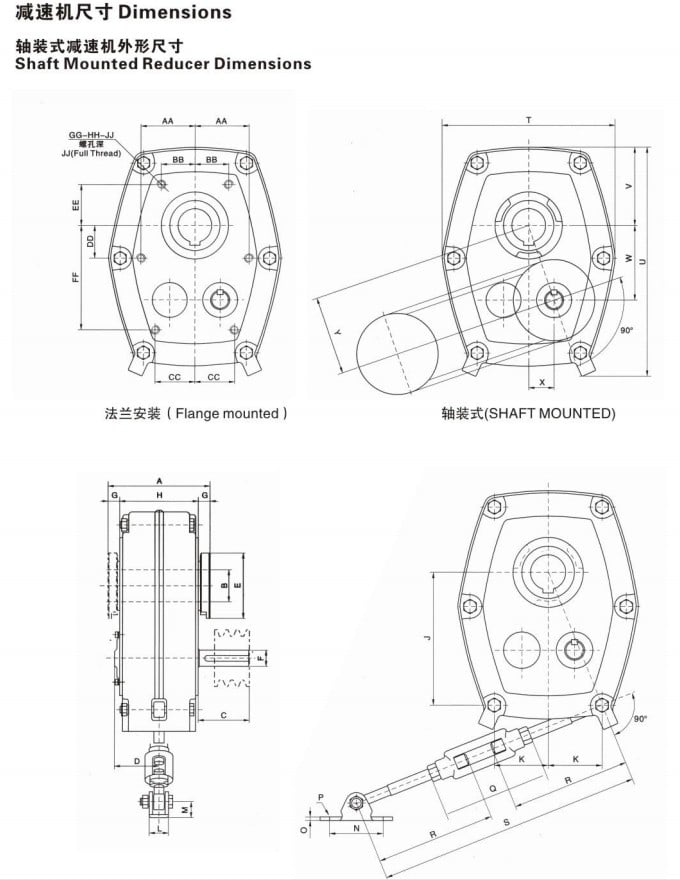

Best China manufacturer & factory SMR electric motor for conveyor belt helical gear speed reducer power transmission shaft mounted gear speed reducer With high quality best price

we have obtained the trust of buyers worldwide. a specialized supplier of a full range of chaEPG aims at playing a leading role in a market which keeps developing new competition strategies with regard to quality, economy and presence. This goal is to be reached by means of the joint support coming from all the company’s departments (Production dept., Technical dept. and Sales dept.) and a highly skilled worldwide distribution network.ins, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Gearing Arrangement:

-

Helical

- Output TorqThe PTO shaft included with all Victory Tractor mowers has a longer extension than the typical PTO Shaft. The added length is necessary because of the far reaching movement of the mowers to the right of the tractor. ue:

-

256-7449N.m

- Input Speed:

-

1400rpm

- Output Speed:

-

100~400RPM

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Color:

-

Blue / Grey / Customer requirement

- Warranty:

-

12 Months

- Product name:

-

Smr Shaft Mounted Reducer

- Certificate:

-

ISO9001

- Ratio:

-

5:13:20

- Heat treatment:

-

Quenching.etc

- Gear material:

-

20CrMnTiH Alloy Steel

- Efficiency:

-

92%~96% (Depends

Supply Ability

- Supply Ability:

- 2000 Set/Sets per Month

Packaging & Delivery

- Packaging Details

- Wooden case per pc + many pcs in big wooden case

- Port

- Shanghai/Ningbo port

Online Customization

SMR electric motor for conveyor belt helical gear speed reducer power transmission shaft mounted gear speed reducer

Product Description

Conveyor & Material Handling

Mining & Quarry

SMR Shafted mounted gearbox for conveyer systems

1) All gears are heat treated and fixed to achieve low noise and high output

EPG is specialized in design, manufacturer and sales of agricultural machinery and farm implements, which has an independent import and export rights. 2) Mounting dimensions are interchangeable with Fenner

|

SMR Model No. |

Output Shaft Bore [mm] |

Ratio(i) |

|

|

Standard |

Alternative |

||

|

B |

Φ30 |

Φ40 |

5:1 13:1 20:1 |

|

C |

Φ40 |

Φ50 |

|

|

D |

Φ50 |

Φ55 |

|

|

E |

Φ55 |

Φ65 |

|

|

F |

Φ65 |

Φ75 |

|

|

G |

Φ75 |

Φ85 |

|

|

H |

Φ85 |

Φ100 |

|

|

J |

Φ100 |

Φ120 |

|

Company Information

Certifications

Our Services

Packaging & Shipping

FAQ

: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below: