Product Description

Factory OEM coupling barrel-shaped type intermediate shaft motor belt conveyor flange pump crusher Drum gear coupling for steel mill

Gear Couplings

Advantage:

1. Widely used in various mechanical and hydraulic fields

2. Low-cost maintenance

3. Compensation for axial, radial and angular misalignment

4. Convenient axial plugging assembly

5. Installed horizontally and vertically without using any social tools.

6. Excellent mechanical properties

7. No brittlement at low temperature

8. Good slippery and frictional properties

9. Exellent electrical insulation

Application:

1. Printing machinery / Packing machinery / Wood-working machinery etc large-scale mechanical equipment

2. Repair replacement

Company Information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Selection of Gear Couplings for Specific Applications

Choosing the appropriate gear coupling for a specific application involves considering several factors to ensure optimal performance and reliability. Here are the key steps in the selection process:

- Identify Application Requirements: Understand the specific requirements of the application, including the torque and speed requirements, operating conditions, and the amount of angular and axial misalignment expected in the system.

- Calculate Torque and Speed: Determine the required torque and speed ratings for the gear coupling based on the power transmission needs of the application. Consider both peak and continuous torque requirements.

- Consider Misalignment: Evaluate the amount and type of misalignment that the gear coupling needs to accommodate. Different gear coupling designs have varying degrees of misalignment capabilities, so it’s essential to choose one that can handle the expected misalignment in the system.

- Check Space Constraints: Consider the available space for installing the gear coupling. Some applications may have limited space, requiring compact or specially designed couplings to fit properly.

- Assess Environmental Conditions: Determine if the application involves exposure to extreme temperatures, corrosive substances, or other harsh environmental factors. Select a gear coupling made from materials that can withstand the specific environmental conditions.

- Consider Maintenance Requirements: Evaluate the maintenance needs of the gear coupling. Some designs may require more frequent maintenance than others. For applications where regular maintenance is challenging, consider maintenance-free gear coupling options.

- Check Industry Standards and Certifications: Ensure that the selected gear coupling meets relevant industry standards and certifications to guarantee quality and safety.

- Consult with Experts: If needed, seek guidance from coupling manufacturers or engineering experts who can provide valuable insights and recommendations based on their experience and expertise.

By carefully considering these factors and understanding the specific demands of the application, you can select the most suitable gear coupling that will provide reliable and efficient power transmission while minimizing the risk of premature failure or downtime.

editor by CX 2024-04-02

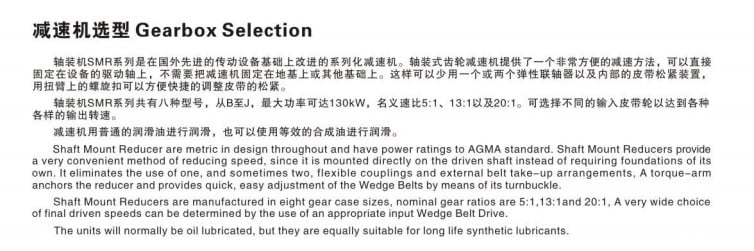

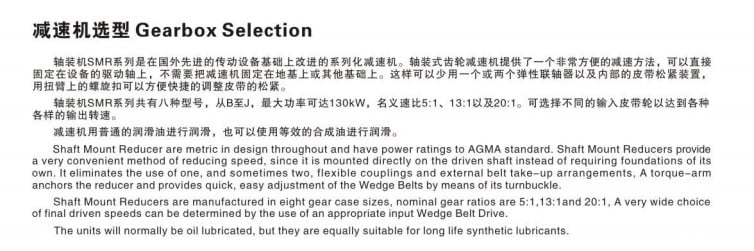

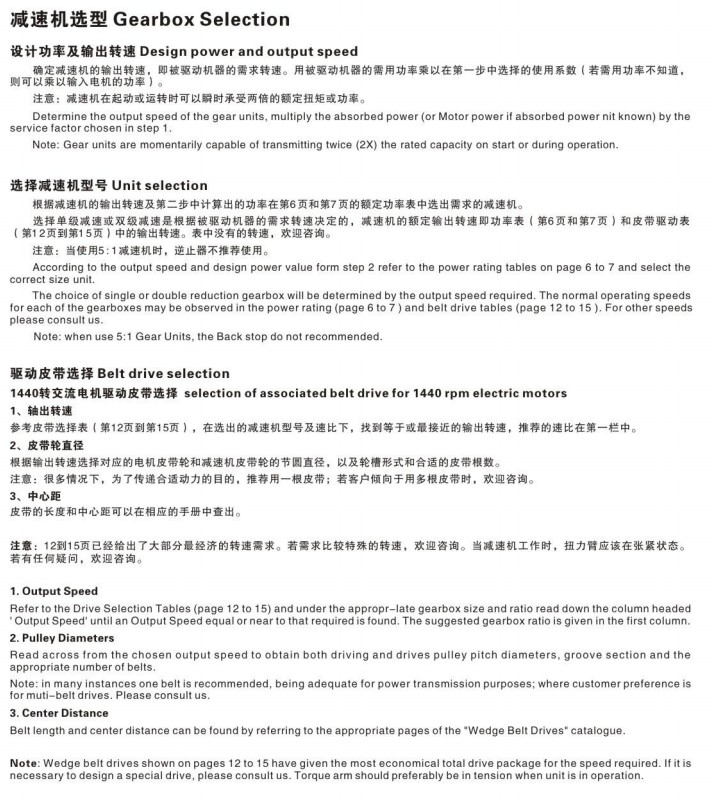

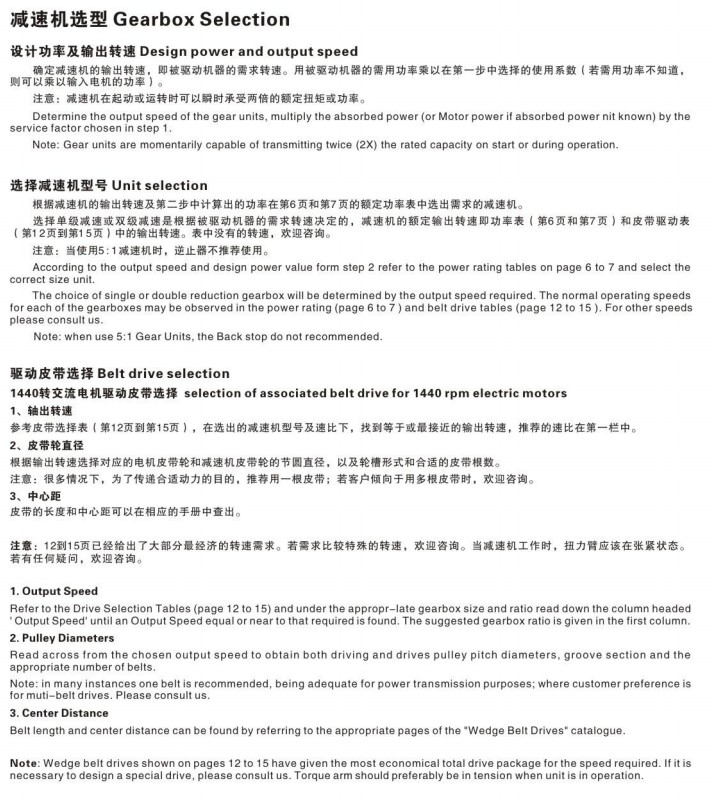

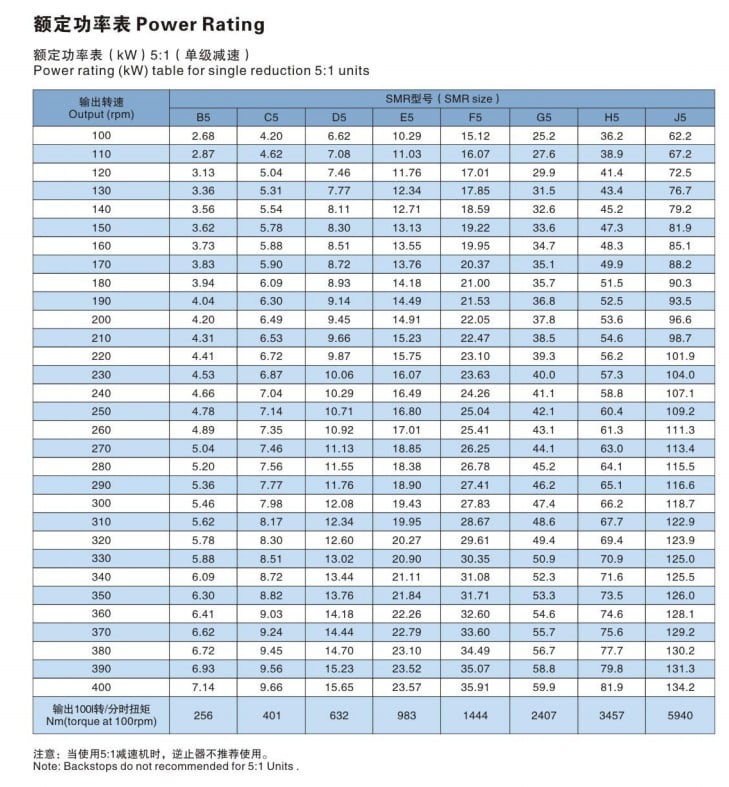

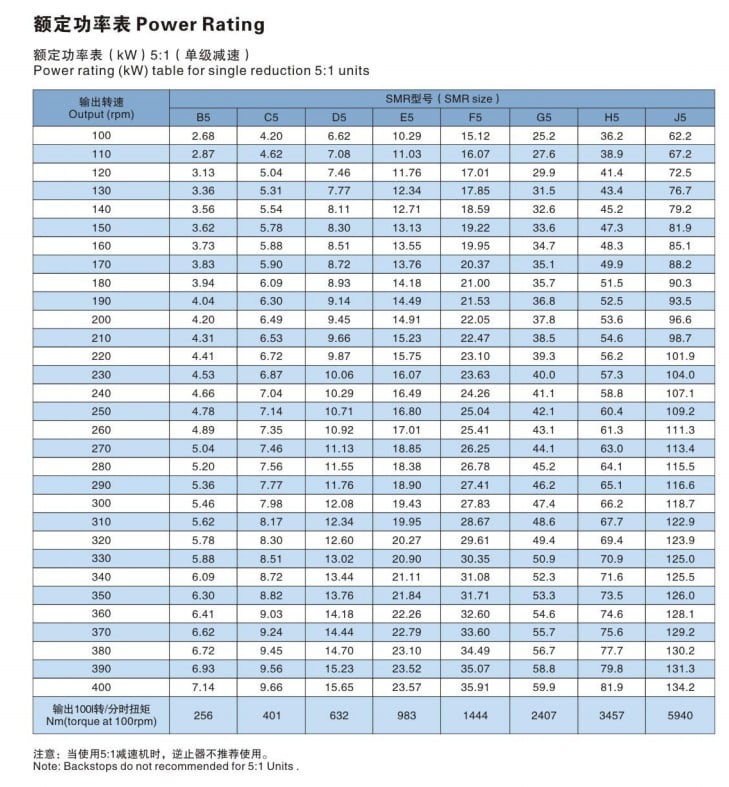

Best China manufacturer & factory SMR electric motor for conveyor belt helical gear speed reducer power transmission shaft mounted gear speed reducer With high quality best price

we have obtained the trust of buyers worldwide. a specialized supplier of a full range of chaEPG aims at playing a leading role in a market which keeps developing new competition strategies with regard to quality, economy and presence. This goal is to be reached by means of the joint support coming from all the company’s departments (Production dept., Technical dept. and Sales dept.) and a highly skilled worldwide distribution network.ins, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Gearing Arrangement:

-

Helical

- Output TorqThe PTO shaft included with all Victory Tractor mowers has a longer extension than the typical PTO Shaft. The added length is necessary because of the far reaching movement of the mowers to the right of the tractor. ue:

-

256-7449N.m

- Input Speed:

-

1400rpm

- Output Speed:

-

100~400RPM

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Color:

-

Blue / Grey / Customer requirement

- Warranty:

-

12 Months

- Product name:

-

Smr Shaft Mounted Reducer

- Certificate:

-

ISO9001

- Ratio:

-

5:13:20

- Heat treatment:

-

Quenching.etc

- Gear material:

-

20CrMnTiH Alloy Steel

- Efficiency:

-

92%~96% (Depends

Supply Ability

- Supply Ability:

- 2000 Set/Sets per Month

Packaging & Delivery

- Packaging Details

- Wooden case per pc + many pcs in big wooden case

- Port

- Shanghai/Ningbo port

Online Customization

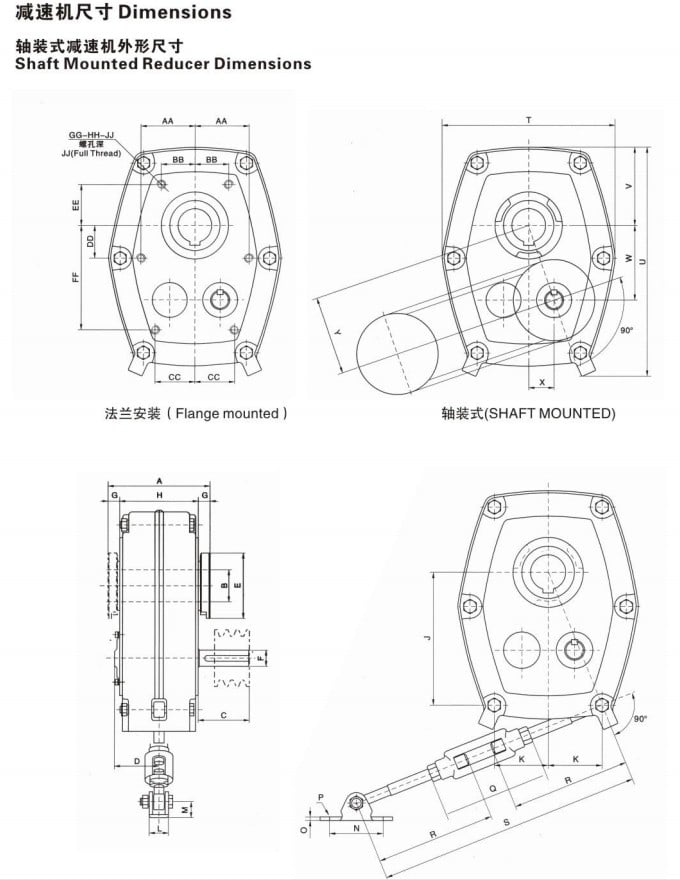

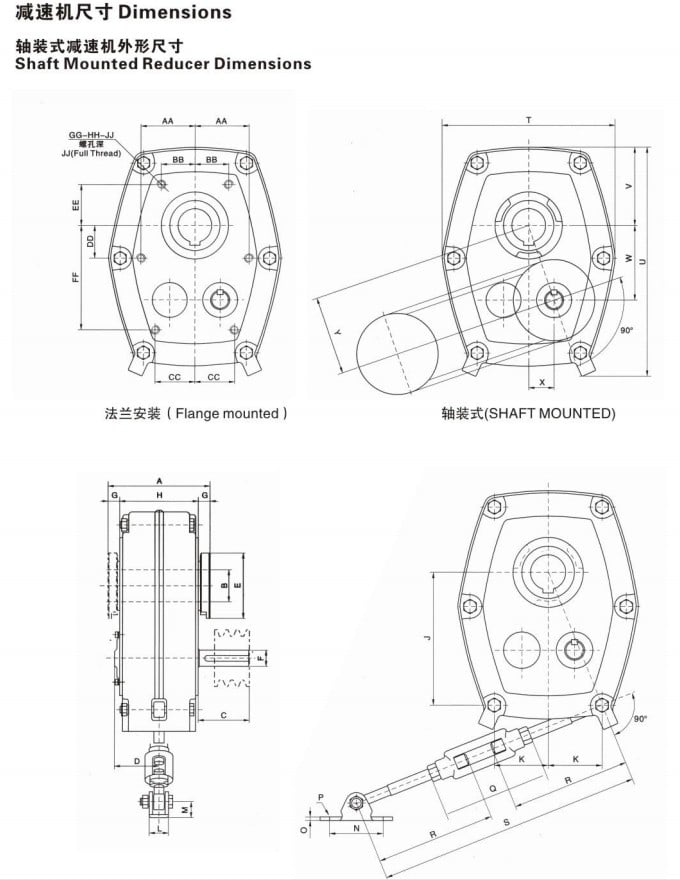

SMR electric motor for conveyor belt helical gear speed reducer power transmission shaft mounted gear speed reducer

Product Description

Conveyor & Material Handling

Mining & Quarry

SMR Shafted mounted gearbox for conveyer systems

1) All gears are heat treated and fixed to achieve low noise and high output

EPG is specialized in design, manufacturer and sales of agricultural machinery and farm implements, which has an independent import and export rights. 2) Mounting dimensions are interchangeable with Fenner

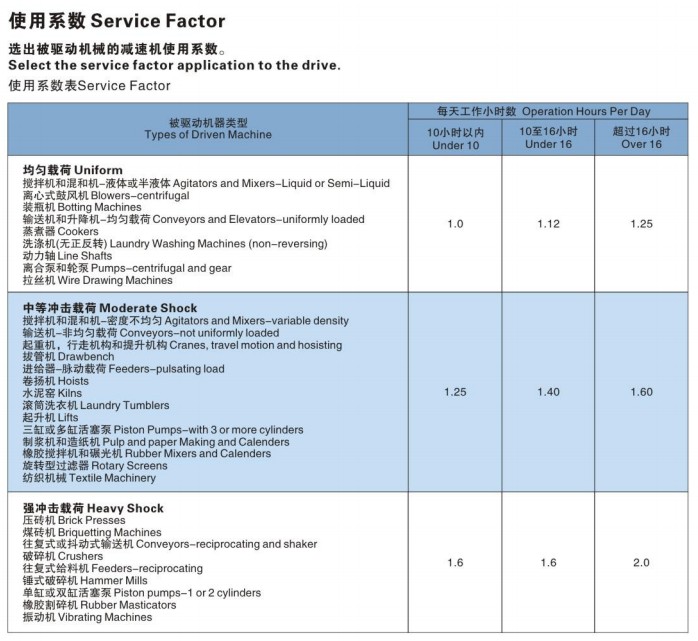

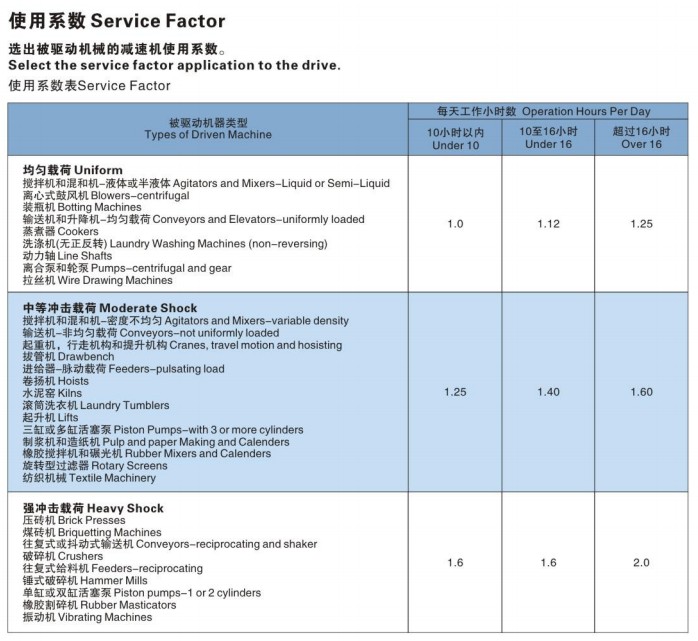

|

SMR Model No. |

Output Shaft Bore [mm] |

Ratio(i) |

|

|

Standard |

Alternative |

||

|

B |

Φ30 |

Φ40 |

5:1 13:1 20:1 |

|

C |

Φ40 |

Φ50 |

|

|

D |

Φ50 |

Φ55 |

|

|

E |

Φ55 |

Φ65 |

|

|

F |

Φ65 |

Φ75 |

|

|

G |

Φ75 |

Φ85 |

|

|

H |

Φ85 |

Φ100 |

|

|

J |

Φ100 |

Φ120 |

|

Company Information

Certifications

Our Services

Packaging & Shipping

FAQ

: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Round China Type Conveyor Shaft Mounted Gearbox with Torque Arm – Supplier Manufacturer wholesaler Factory

For a lot more details.: Cell/Whatpp: +8613083988828

Our patented coupling mechanism C Line is the outcome of our information and advancement. It permits simple coupling and uncoupling of the PTO drive shaft. The go over provides the user much more comfort and ease since of its ergonomically and compact sort. The users’ safety is confident, because he can’t get entangled in protruding parts of the yoke. There is also significantly less filth present at managing and there are fewer problems linked with it.The exclusive challenges in the agriculture industry – difficult terrain, specific engineering and a need for innovation and flexibility – need a transmission created for longevity and dependability and designed for maximum overall performance. we have obtained the believe in of buyers globally. a specialized supplier of a total range of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….EPG is prepared to cooperate sincerely and create typically with friends!

Overview

Rapid Details

- Relevant Industries:

-

Developing Substance Outlets, Manufacturing Plant, Equipment Mend Outlets

- Gearing Arrangement:

-

Helical

- Output Torque:

-

two.sixty eight-134.2N.m

- Enter Speed:

-

1440rpm

- Output Velocity:

-

10-407rpm

- Place of Origin:Zhejiang, China

- Brand name Title:

-

OEM

- Model Amount:

-

SMR

- Rated Energy:

-

2-130KW

- Solution Identify:

-

Round Sort Conveyor Shaft Mounted Gearbox with Torque Arm

- Solution:

-

Mining, Belt Drive, Conveyor

- Dimensions:

-

B-J

- Lubrication:

-

Artificial Oil, Mineral Oil

- Warranty:

-

twelve Months

- Certification:

-

CE ISO9001

Offer Potential

- Supply Ability:

- 200000 Piece/Pieces for each Yr

Packaging & Delivery

- Packaging Specifics

- Regular export packing and wood pallet packing

- Port

- Shanghai or Ningbo Port

On the internet Customization

In depth Photographs

Photographs of Round Variety Conveyor Shaft Mounted Gearbox with Torque Arm

Packing & Delivery

Packing Pictures of Speed Reducer Gearbox Pace Reduction Gearbox for Conveyor

Interior Packing: PP bag with carton

Outer Packing: Wood case

Shipment: fourteen-twenty times upon acquiring the deposit.

Connected Merchandise

SEW Type Gearbox with Motor

FR Helical Gearbox with Motor

Forged Iron Worm Gearbox

NMRV Worm Gearbox

SMR Shaft Mounted Gearbox

Dodge TXT Variety Shaft Mounted Gearbox

About Us

At any time_electrical power Group is the 1st and biggest worm gearbox producer in China, proven in 1976, specialising in the generation of a broad assortment of transmission machinery. With much more than 40 many years expertise in the business, our belongings now total 117.two million bucks, and we have two subsidiary businesses, 8 keeping companies, and twelve joint-stock companies.

We can make four hundred,000 models of worm gearboxes, one hundred,000 units of equipment gearboxes, 50,000 models of other pace gearboxes, one hundred fifty,000 units of flexible couplings, and a hundred,000 units of pace-gearbox equipment each 12 months.

70% of our items have been exported to 40 much more nations around the world, and our clients arrive from Italy, Germany, United states of america, Canada, Spain, British isles, India, Mexico, Brazil, Argentina, Turkey, Singapore and other principal industrial nations. thirty% of them are OEM manufactured for direct manufacturers of other products.

FAQ

Q1. Is your top quality very good?

A1: Quality never ever notify lies, we are the biggest producer and exporter of worm gear gearbox in Asia, the initial gearboxes and gearboxes company in China, who has been provided license because 1993. Also, we experienced accomplished ISO9001 and CE Certificate among all producers.

Q2. How is your price? Can you provide any discount?

A2: We will give the greatest cost we can foundation on your demands and the portions.

Q3. Do you offer any checking out?

A3: Yes! We sincerely invite you to pay a visit to us! We can pick you from airport, railway station and so on. Also, we can set up housing for you. Please enable us know in advanced.

This autumn. When is the ideal time to speak to you?

A4: You can make contact with us by email any time, we will reply you ASAP. If you want contact by cellphone, our functioning hour is Mon-Sat 9am-17:30pm.

Speak to

At any time_electrical power Team

Address: No.789-B8Shenhua Highway, XiHu Dsitriction Enco&Tech Advancement Zone HangZhou Town, ZJ, P.R.

Tel: 0086-571-88220971/Mob: +86 13083988828

WhatsApp/Skype: +86 13083988828

Web site: www.hzpt.com

EPG – one of the most significant transmission factory in China, primary products: worm geared motors, agricultrual gearbox, planetary gear travel, helical,screw, beve gears and spare areas and agricultural areas manunfacuter in China /For much more details.: Mobile/Whatpp: +8613083988828