Product Description

Stainless Steel Coupling Gear Rigid Roller Chain Fluid Tyre Grid Jaw Spider HRC Nm Motor Flange Gear Pump Rubber Spline Shaft Flexible Universal Joint Coupling

Product Description

Main products

Coupling refers to a device that connects 2 shafts or shafts and rotating parts, rotates together during the transmission of motion and power, and does not disengage under normal conditions. Sometimes it is also used as a safety device to prevent the connected parts from bearing excessive load, which plays the role of overload protection.

Couplings can be divided into rigid couplings and flexible couplings.

Rigid couplings do not have buffering property and the ability to compensate the relative displacement of 2 axes. It is required that the 2 axes be strictly aligned. However, such couplings are simple in structure, low in manufacturing cost, convenient in assembly and disassembly, and maintenance, which can ensure that the 2 axes are relatively neutral, have large transmission torque, and are widely used. Commonly used are flange coupling, sleeve coupling and jacket coupling.

Flexible coupling can also be divided into flexible coupling without elastic element and flexible coupling with elastic element. The former type only has the ability to compensate the relative displacement of 2 axes, but cannot cushion and reduce vibration. Common types include slider coupling, gear coupling, universal coupling and chain coupling; The latter type contains elastic elements. In addition to the ability to compensate the relative displacement of 2 axes, it also has the functions of buffering and vibration reduction. However, due to the strength of elastic elements, the transmitted torque is generally inferior to that of flexible couplings without elastic elements. Common types include elastic sleeve pin couplings, elastic pin couplings, quincunx couplings, tire type couplings, serpentine spring couplings, spring couplings, etc

Coupling performance

1) Mobility. The movability of the coupling refers to the ability to compensate the relative displacement of 2 rotating components. Factors such as manufacturing and installation errors between connected components, temperature changes during operation and deformation under load all put CHINAMFG requirements for mobility. The movable performance compensates or alleviates the additional load between shafts, bearings, couplings and other components caused by the relative displacement between rotating components.

(2) Buffering. For the occasions where the load is often started or the working load changes, the coupling shall be equipped with elastic elements that play the role of cushioning and vibration reduction to protect the prime mover and the working machine from little or no damage.

(3) Safe, reliable, with sufficient strength and service life.

(4) Simple structure, easy to assemble, disassemble and maintain.

How to select the appropriate coupling type

The following items should be considered when selecting the coupling type.

1. The size and nature of the required transmission torque, the requirements for buffering and damping functions, and whether resonance may occur.

2. The relative displacement of the axes of the 2 shafts is caused by manufacturing and assembly errors, shaft load and thermal expansion deformation, and relative movement between components.

3. Permissible overall dimensions and installation methods, and necessary operating space for assembly, adjustment and maintenance. For large couplings, they should be able to be disassembled without axial movement of the shaft.

In addition, the working environment, service life, lubrication, sealing, economy and other conditions should also be considered, and a suitable coupling type should be selected by referring to the characteristics of various couplings.

If you cannot determine the type, you can contact our professional engineer

Related products

Company Profile

Our Equipments

Main production equipment:

Large lathe, surface grinder, milling machine, gear shaper, spline milling machine, horizontal broaching machine, gear hobbing machine, shaper, slotting machine, bench drilling machine, radial drilling machine, boring machine, band sawing machine, horizontal lathe, end milling machine, crankshaft grinder, CNC milling machine, casting equipment, etc.

Inspection equipment:

Dynamic balance tester, high-speed intelligent carbon and sulfur analyzer, Blochon optical hardness tester, Leeb hardness tester, magnetic yoke flaw detector, special detection, modular fixture (self-made), etc.

Machining equipments

Heat equipment

Our Factory

Application – Photos from our partner customers

Company Profile

Our leading products are mechanical transmission basic parts – couplings, mainly including universal couplings, drum gear couplings, elastic couplings and other 3 categories of more than 30 series of varieties. It is widely used in metallurgical steel rolling, wind power, hydropower, mining, engineering machinery, petrochemical, lifting, paper making, rubber, rail transit, shipbuilding and marine engineering and other industries.

Our factory takes the basic parts of national standards as the benchmark, has more than 40 years of coupling production experience, takes “scientific management, pioneering and innovation, ensuring quality and customer satisfaction” as the quality policy, and aims to continuously provide users with satisfactory products and services. The production is guided by reasonable process, and the ISO9001:2015 quality management system standard is strictly implemented. We adhere to the principle of continuous improvement and innovation of coupling products. In recent years, it has successfully developed 10 national patent products such as SWF cross shaft universal coupling, among which the double cross shaft universal joint has won the national invention patent, SWF cross shaft universal coupling has won the new product award of China’s general mechanical parts coupling industry and the ZHangZhoug Province new product science and technology project.

Our factory has strong technical force, excellent process equipment, complete professional production equipment, perfect detection means, excellent after-sales service, various products and complete specifications. At the same time, we can provide the design and manufacturing of special non-standard products according to the needs of users. Our products sell well at home and abroad, and are trusted by the majority of users. We sincerely welcome friends from all walks of life at home and abroad to visit and negotiate for common development.p

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Advantages of Using Gear Couplings in Mechanical Systems

Gear couplings offer several advantages that make them a popular choice for connecting shafts in mechanical systems. Some of the key advantages include:

- High Torque Capacity: Gear couplings are designed to handle high torque loads, making them suitable for heavy-duty applications that require efficient power transmission.

- Misalignment Compensation: One of the significant advantages of gear couplings is their ability to accommodate various types of misalignment between the connected shafts, including angular, parallel, and axial misalignments. This flexibility helps reduce stress on the connected equipment and improves overall system performance.

- Shock and Vibration Dampening: The meshing of the gear teeth in a gear coupling provides inherent shock and vibration dampening capabilities. This feature helps protect the connected components from sudden impact loads and reduces wear and tear.

- Compact Design: Gear couplings have a compact design, which allows for easy installation even in tight spaces or limited clearance applications.

- High Reliability: Due to their robust construction and excellent torque transmission capabilities, gear couplings are known for their reliability and durability, ensuring long service life in demanding conditions.

- Easy Maintenance: Gear couplings are relatively easy to maintain. Regular inspection and proper lubrication help ensure smooth operation and extend the coupling’s life span.

- Wide Range of Sizes and Configurations: Gear couplings are available in various sizes and configurations, making it possible to find a suitable coupling for a wide range of applications.

- Suitable for High-Speed Applications: Gear couplings can be designed to handle high rotational speeds, making them suitable for applications where high-speed shaft connections are required.

- Temperature and Environment Tolerance: Gear couplings are often made from materials that can withstand high temperatures and harsh environmental conditions, making them suitable for use in challenging industrial settings.

Overall, gear couplings provide a reliable and efficient means of transmitting power between rotating shafts, particularly in heavy-duty and high-torque applications. Their ability to accommodate misalignment and dampen vibrations helps protect connected equipment and contributes to the smooth operation of mechanical systems.

editor by CX 2024-01-03

China manufacturer Flexible Drive Pipe Spline Shaft Disc Flange Gear Rubber Jaw Motor Spacer Beam Rigid Fluid Chain Nm Mh HRC Pin Fenaflex Spacer Elastomeric Coupling gear coupling

Product Description

Flexible Drive Pipe Spline Shaft Disc Flange Gear Rubber Jaw Motor Spacer Beam Rigid Fluid Chain Nm Mh HRC Pin Fenaflex Spacer Elastomeric Coupling

What Industries Commonly Use Gear Couplings for Power Transmission?

Gear couplings are widely used in various industries for power transmission due to their ability to transmit high torque loads and accommodate misalignments. Some of the industries that commonly utilize gear couplings include:

- Steel Industry: Gear couplings are extensively used in the steel industry for connecting heavy-duty equipment like rolling mills, continuous casting machines, and other steel processing machinery.

- Mining and Quarrying: In mining and quarrying applications, gear couplings are employed to transmit power in conveyor systems, crushers, and heavy excavating machinery.

- Pulp and Paper: The pulp and paper industry uses gear couplings in machines like paper mills, pulp refiners, and stock preparation equipment.

- Marine: Gear couplings are utilized in marine propulsion systems, providing a reliable connection between the engine and the propeller shafts.

- Oil and Gas: Gear couplings find use in the oil and gas industry for connecting pumps, compressors, and other equipment used in upstream and downstream operations.

- Power Generation: Gear couplings are employed in power plants to connect generators, turbines, and other rotating equipment.

- Automotive: Gear couplings are used in automotive applications, particularly in heavy-duty vehicles and machinery like off-road vehicles, construction equipment, and agricultural machinery.

- Chemical and Petrochemical: In chemical processing plants, gear couplings are employed in agitators, mixers, and various equipment where power transmission is crucial.

- Cement and Aggregate: Gear couplings are used in cement plants and aggregate processing equipment for power transmission in crushers, kilns, and conveyors.

These are just a few examples, and gear couplings can be found in various other industries where reliable power transmission is essential. Their robust design and ability to withstand harsh operating conditions make them a popular choice for heavy-duty applications across different sectors.

editor by CX 2023-12-04

China factory Flexible Flex Fluid Chain Jaw Flange Gear Rigid Spacer Pin HRC Mh Nm Universal Fenaflex Oldham Spline Clamp Tyre Grid Hydraulic Servo Motor Shaft Coupling gear coupling

Product Description

Flexible flex Fluid Chain Jaw flange Gear Rigid Spacer PIN HRC MH NM universal Fenaflex Oldham spline clamp tyre grid hydraulic servo motor shaft Coupling

Product Description

The function of Shaft coupling:

1. Shafts for connecting separately manufactured units such as motors and generators.

2. If any axis is misaligned.

3. Provides mechanical flexibility.

4. Absorb the transmission of impact load.

5. Prevent overload

We can provide the following couplings.

| Rigid coupling | Flange coupling | Oldham coupling |

| Sleeve or muff coupling | Gear coupling | Bellow coupling |

| Split muff coupling | Flexible coupling | Fluid coupling |

| Clamp or split-muff or compression coupling | Universal coupling | Variable speed coupling |

| Bushed pin-type coupling | Diaphragm coupling | Constant speed coupling |

Company Profile

We are an industrial company specializing in the production of couplings. It has 3 branches: steel casting, forging, and heat treatment. Main products: cross shaft universal coupling, drum gear coupling, non-metallic elastic element coupling, rigid coupling, etc.

The company mainly produces the industry standard JB3241-91 swap JB5513-91 swc. JB3242-93 swz series universal coupling with spider type. It can also design and produce various non-standard universal couplings, other couplings, and mechanical products for users according to special requirements. Currently, the products are mainly sold to major steel companies at home and abroad, the metallurgical steel rolling industry, and leading engine manufacturers, with an annual production capacity of more than 7000 sets.

The company’s quality policy is “quality for survival, variety for development.” In August 2000, the national quality system certification authority audited that its quality assurance system met the requirements of GB/T19002-1994 IDT ISO9002:1994 and obtained the quality system certification certificate with the registration number 0900B5711. It is the first enterprise in the coupling production industry in HangZhou City that passed the ISO9002 quality and constitution certification.

The company pursues the business purpose of “reliable quality, the supremacy of reputation, commitment to business and customer satisfaction” and welcomes customers at home and abroad to choose our products.

At the same time, the company has established long-term cooperative relations with many enterprises and warmly welcomes friends from all walks of life to visit, investigate and negotiate business!

How to use the coupling safely

The coupling is an intermediate connecting part of each motion mechanism, which directly impacts the regular operation of each motion mechanism. Therefore, attention must be paid to:

1. The coupling is not allowed to have more than the specified axis deflection and radial displacement so as not to affect its transmission performance.

2. The bolts of the LINS coupling shall not be loose or damaged.

3. Gear coupling and cross slide coupling shall be lubricated regularly, and lubricating grease shall be added every 2-3 months to avoid severe wear of gear teeth and serious consequences.

4. The tooth width contact length of gear coupling shall not be less than 70%; Its axial displacement shall not be more significant than 5mm

5. The coupling is not allowed to have cracks. If there are cracks, it needs to be replaced (they can be knocked with a small hammer and judged according to the sound).

6. The keys of LINS coupling shall be closely matched and shall not be loosened.

7. The tooth thickness of the gear coupling is worn. When the lifting mechanism exceeds 15% of the original tooth thickness, the operating mechanism exceeds 25%, and the broken tooth is also scrapped.

8. If the elastic ring of the pin coupling and the sealing ring of the gear coupling is damaged or aged, they should be replaced in time.

Certifications

Packaging & Shipping

How Does a Gear Coupling Protect Connected Equipment from Shock Loads and Vibrations?

Gear couplings are designed to provide excellent protection to connected equipment from shock loads and vibrations, making them ideal for use in demanding and heavy-duty applications. The design and features of gear couplings that contribute to this protection include:

- Flexible and Rigid Elements: Gear couplings consist of two hubs with external gears that mesh together. Between these two hubs, there is a center sleeve with internal gear teeth. The center sleeve acts as a flexible element, while the outer hubs act as rigid elements. This combination allows the gear coupling to transmit torque while absorbing and dampening shock loads and vibrations.

- Misalignment Compensation: Gear couplings can accommodate angular, parallel, and axial misalignment between shafts. When the connected equipment experiences misalignment due to dynamic forces or shock loads, the gear coupling can flex and adjust to these changes, preventing excessive stress on the shafts and equipment.

- High Torsional Stiffness: Gear couplings offer high torsional stiffness, meaning they have minimal angular deflection under load. This stiffness helps maintain precise alignment and reduces the likelihood of damage to the connected equipment caused by misalignment-induced vibrations.

- Load Distribution: The toothed gear design of gear couplings ensures a large surface area of contact between the gears. This spreads the torque evenly across the gear teeth, resulting in a uniform distribution of load and reducing the concentration of stress on specific areas.

- Damping Characteristics: The flexible center sleeve in the gear coupling acts as a damping element that absorbs and dissipates vibrations, further protecting the connected equipment from harmful oscillations.

- High-Speed Balancing: Gear couplings are precisely balanced during manufacturing to minimize vibrations and ensure smooth operation even at high speeds. Proper balancing helps prevent resonances and reduces the impact of shock loads on the connected equipment.

By effectively absorbing and dampening shock loads and vibrations, gear couplings extend the life of the connected equipment and surrounding components, reduce maintenance requirements, and contribute to a more reliable and efficient mechanical system. However, it is essential to select the appropriate size and type of gear coupling based on the specific application and operating conditions to ensure optimal protection and performance.

editor by CX 2023-12-01

China factory Flange Cast Iron Coupling Steel Universal Joint Cardan Pump Rubber Motor Disc Curved Tooth Flex Rigid Drive Shaft Nm Yox Fluid Jaw Flexible Chain Gear Couplings gear coupling

Product Description

Flange Cast Iron Coupling Steel Universal Joint Cardan Pump Rubber Motor Disc CHINAMFG Flex Rigid Drive Shaft NM yox Fluid Jaw Flexible Chain Gear Couplings

Manufacturer of Couplings, Fluid Coupling, JAW Coupling, can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Coupling is a jaw type coupling that works for a variety of light duty to heavy duty motors used in electric power transmission.

This is 1 of our safest types of products. The reason being that these couplings work even when the elastomer fails and there is no metal to metal contact.

They perform in well-standing oil, grease, moisture, sand, and dirt and nearly 850,000 bore combinations that can be customised as per the customer’s needs.

They are used in light-weight, medium, or heavy electrical motors and devices for power transmission through internal combustion.

Production workshop:

Company information:

Advantages of Using Gear Couplings in Mechanical Systems

Gear couplings offer several advantages that make them a popular choice for connecting shafts in mechanical systems. Some of the key advantages include:

- High Torque Capacity: Gear couplings are designed to handle high torque loads, making them suitable for heavy-duty applications that require efficient power transmission.

- Misalignment Compensation: One of the significant advantages of gear couplings is their ability to accommodate various types of misalignment between the connected shafts, including angular, parallel, and axial misalignments. This flexibility helps reduce stress on the connected equipment and improves overall system performance.

- Shock and Vibration Dampening: The meshing of the gear teeth in a gear coupling provides inherent shock and vibration dampening capabilities. This feature helps protect the connected components from sudden impact loads and reduces wear and tear.

- Compact Design: Gear couplings have a compact design, which allows for easy installation even in tight spaces or limited clearance applications.

- High Reliability: Due to their robust construction and excellent torque transmission capabilities, gear couplings are known for their reliability and durability, ensuring long service life in demanding conditions.

- Easy Maintenance: Gear couplings are relatively easy to maintain. Regular inspection and proper lubrication help ensure smooth operation and extend the coupling’s life span.

- Wide Range of Sizes and Configurations: Gear couplings are available in various sizes and configurations, making it possible to find a suitable coupling for a wide range of applications.

- Suitable for High-Speed Applications: Gear couplings can be designed to handle high rotational speeds, making them suitable for applications where high-speed shaft connections are required.

- Temperature and Environment Tolerance: Gear couplings are often made from materials that can withstand high temperatures and harsh environmental conditions, making them suitable for use in challenging industrial settings.

Overall, gear couplings provide a reliable and efficient means of transmitting power between rotating shafts, particularly in heavy-duty and high-torque applications. Their ability to accommodate misalignment and dampen vibrations helps protect connected equipment and contributes to the smooth operation of mechanical systems.

editor by CX 2023-11-30

China wholesaler Flexible Flex Fluid Chain Jaw Flange Gear Rigid Spacer Pin HRC Mh Nm Universal Fenaflex Oldham Spline Clamp Tyre Grid Hydraulic Servo Motor Shaft Coupling gear coupling

Product Description

Flexible flex Fluid Chain Jaw flange Gear Rigid Spacer PIN HRC MH NM universal Fenaflex Oldham spline clamp tyre grid hydraulic servo motor shaft Coupling

Product Description

The function of Shaft coupling:

1. Shafts for connecting separately manufactured units such as motors and generators.

2. If any axis is misaligned.

3. Provides mechanical flexibility.

4. Absorb the transmission of impact load.

5. Prevent overload

We can provide the following couplings.

| Rigid coupling | Flange coupling | Oldham coupling |

| Sleeve or muff coupling | Gear coupling | Bellow coupling |

| Split muff coupling | Flexible coupling | Fluid coupling |

| Clamp or split-muff or compression coupling | Universal coupling | Variable speed coupling |

| Bushed pin-type coupling | Diaphragm coupling | Constant speed coupling |

Company Profile

We are an industrial company specializing in the production of couplings. It has 3 branches: steel casting, forging, and heat treatment. Main products: cross shaft universal coupling, drum gear coupling, non-metallic elastic element coupling, rigid coupling, etc.

The company mainly produces the industry standard JB3241-91 swap JB5513-91 swc. JB3242-93 swz series universal coupling with spider type. It can also design and produce various non-standard universal couplings, other couplings, and mechanical products for users according to special requirements. Currently, the products are mainly sold to major steel companies at home and abroad, the metallurgical steel rolling industry, and leading engine manufacturers, with an annual production capacity of more than 7000 sets.

The company’s quality policy is “quality for survival, variety for development.” In August 2000, the national quality system certification authority audited that its quality assurance system met the requirements of GB/T19002-1994 IDT ISO9002:1994 and obtained the quality system certification certificate with the registration number 0900B5711. It is the first enterprise in the coupling production industry in HangZhou City that passed the ISO9002 quality and constitution certification.

The company pursues the business purpose of “reliable quality, the supremacy of reputation, commitment to business and customer satisfaction” and welcomes customers at home and abroad to choose our products.

At the same time, the company has established long-term cooperative relations with many enterprises and warmly welcomes friends from all walks of life to visit, investigate and negotiate business!

How to use the coupling safely

The coupling is an intermediate connecting part of each motion mechanism, which directly impacts the regular operation of each motion mechanism. Therefore, attention must be paid to:

1. The coupling is not allowed to have more than the specified axis deflection and radial displacement so as not to affect its transmission performance.

2. The bolts of the LINS coupling shall not be loose or damaged.

3. Gear coupling and cross slide coupling shall be lubricated regularly, and lubricating grease shall be added every 2-3 months to avoid severe wear of gear teeth and serious consequences.

4. The tooth width contact length of gear coupling shall not be less than 70%; Its axial displacement shall not be more significant than 5mm

5. The coupling is not allowed to have cracks. If there are cracks, it needs to be replaced (they can be knocked with a small hammer and judged according to the sound).

6. The keys of LINS coupling shall be closely matched and shall not be loosened.

7. The tooth thickness of the gear coupling is worn. When the lifting mechanism exceeds 15% of the original tooth thickness, the operating mechanism exceeds 25%, and the broken tooth is also scrapped.

8. If the elastic ring of the pin coupling and the sealing ring of the gear coupling is damaged or aged, they should be replaced in time.

Certifications

Packaging & Shipping

Are There Any Safety Considerations When Using Gear Couplings in Rotating Machinery?

Yes, there are several safety considerations to keep in mind when using gear couplings in rotating machinery:

- Guarding: It is essential to provide adequate guarding around gear couplings and other rotating parts to prevent accidental contact with moving components. Proper guarding helps protect personnel from potential entanglement, pinch points, or other hazards.

- Maintenance and Inspection: Regular maintenance and inspection of gear couplings are critical to ensure their safe and reliable operation. This includes checking for signs of wear, lubrication levels, and any abnormalities in the coupling’s performance.

- Lubrication: Proper lubrication of the gear coupling is essential to reduce friction, wear, and heat generation. Follow the manufacturer’s guidelines for lubrication intervals and use the recommended lubricant type.

- Temperature Monitoring: In high-speed or high-temperature applications, it is advisable to monitor the temperature of the gear coupling during operation. Excessive heat can indicate issues with lubrication or alignment that need immediate attention.

- Alignment: Ensure proper alignment of the connected shafts and gear coupling during installation. Misalignment can lead to increased wear, vibration, and premature failure of the coupling.

- Torque and Speed Limitations: Adhere to the specified torque and speed limitations provided by the gear coupling manufacturer. Operating the coupling beyond its rated capacity can result in failures and safety hazards.

- Emergency Shutdown: Machinery equipped with gear couplings should have an accessible and effective emergency shutdown mechanism to quickly stop the equipment in case of emergencies.

- Training: Provide proper training to personnel who work with or around machinery equipped with gear couplings. Training should cover safety protocols, coupling maintenance procedures, and the potential hazards associated with the equipment.

- Replace Damaged Couplings: If a gear coupling shows signs of damage, excessive wear, or malfunction, it should be replaced promptly to prevent potential accidents or equipment breakdowns.

Following these safety considerations can help ensure the safe and efficient operation of rotating machinery equipped with gear couplings. Regular maintenance, adherence to safety guidelines, and proper training contribute to a safer working environment and prolong the service life of gear couplings and the connected equipment.

editor by CX 2023-09-30

in Culiacan Mexico sales price shop near me near me shop factory supplier 1500W Gh AC Gear Horizontal Motor with 32mm Output Shaft manufacturer best Cost Custom Cheap wholesaler

Thanks to our extensive product variety and prosperous encounters in this business, ensures the stability and regularity of the essential purpose of factors. Our product selection contains all varieties of helical gear, spur equipment, bevel equipment, gear rack, worm equipment, sprockets,chains, bearings.

Item description

CH/CV horizontal EPTT , helical EPT motor (with the brake) frequently known as reduction motor small EPT motors , is a variety of velocity EPT motor and motor (motor) the integration of the human body. This integration physique generally can also be called EPT motor, typically assembled by the integration following complete supply by a expert EPT motor factory . The EPTed motor broadly employed metal sector, EPTTry sector, or assembled with magnetic powEPTTclutch and brake , and so on. Ac EPT motor is EPTTly through the motor, inner combustion engines or other large pace operating EPTT by way of the low rpm ac EPT motor enter shaft of the significantly less quantity of EPT engagement on the output shaft of large EPT to accomplish the goal of the slowdown.

Our reduction EPTed motor Advantage

1,realistic cost with superb top quality

2,shipping in time

three,protected ,reliable ,inexpensive and tough

4,stable EPTT ,peaceful operation

five,smooth working and low noise

six,nice look ,resilient service existence

7,high warmth-radiating efficiency ,large carrying capacity

eight,each and every EPTT must be tested before EPTT

nine.reply in large effectiveness in the course of a single operating day

ten. professional to create EPTT and electric motor .

If there is any issue, you should will not be reluctant to make contact with with me (EVA), U can send us your inquiry. And you will get reaction in one doing work working day.

EPT CATALOGUE :

FAQ

one, Q:what is your MOQ for ac EPEPT ?

A: 1pc is alright for each and every sort electric EPT box motor

two, Q: What about your warranty for your induction pace EPEPT ?

A: a single yr ,but except gentleman-produced destroyed

3, Q: which payment way you can acknowledge ?

A: TT, western union .

four, Q: how about your payment way ?

A: a hundred%payment in EPTd much less $5000 ,thirty% payment in EPTd payment , 70% payment ahead of sending above $5000.

five, Q: how about your EPTT of speed reduction motor ?

A: plywood circumstance ,if dimension is tiny ,we will pack with pallet for considerably less a single container

six, Q: What info should be provided, if I get electric helical EPTed motor from you ?

A: rated EPTT, ratio or output velocity,sort ,voltage , mounting way , quantity , if far more is EPT ,

in Padova Italy sales price shop near me near me shop factory supplier Main Shaft Gear Skating Safety Samsung Watch Plastic Crown Pinion Uchida Pump Sumitomo Motors Rock Climbing Savage Spiral Bevel Snorkel Fitness Custom Motor manufacturer best Cost Custom Cheap wholesaler

we offer chromed bar and tubes for hydualic and pheumatic cylinders. The group has taken portion in the making and revising of ISO/TC100 international chain common several years in good results and hosted the sixteenth ISO/TC100 Global annual meeting in 2004. Because of to our extensive item variety and prosperous experiences in this business,

Principal shaft EPT skating basic safety samsung observe plastic crown pinion uchida pump sumitomo motors rock climbing savage spiral EPTTl snorkel health personalized motor

China manufacturer & factory supplier for cycloidal in Gold Coast Australia reducer cycloidal pin wheel reducer stepless speed variator with motor transmission output shaft With high quality best price & service

engineering class chains & precision roller chains. One strand chain, multi-strand chains, double pitch chains, corrosion resistant chains, self-lubricating chains, attachment chains, leaf chains, and specialty chains.focus in electrical power transmission merchandise Chain,pto shaft, agricultural gearboxes , CATV merchandise, mechanical seal, hydraulic and Pheumatic, and advertising products.

Overview

Quick Details

- Relevant Industries:

-

A worm equipment program is composed of a worm and worm wheel. The worm resembles a screw, which meets with a worm wheel, as demonstrated in the picture. When rotational energy is utilized to the worm, it rotates from the wheel and transfers electricity to the worm wheel. The method is made so that the worm can very easily turn the gear, but the equipment can’t flip the worm. In some patterns, the friction amongst the gear and worm retains the worm in area. This characteristic can be really helpful in some applications. The PTO shaft incorporated with all Victory Tractor mowers has a more time extension than the normal PTO Shaft. The included size is required since of the much achieving movement of the mowers to the appropriate of the tractor.

Manufacturing Plant, Machinery Restore Stores, Foods & Beverage Manufacturing facility, Farms

- Location of Origin:Zhejiang, China

- Model Identify:

-

OEM

- Gearing Arrangement:

-

Cycloidal

- Output Torque:

-

2.6-20000N.m

- Enter Speed:

-

750-3000rpm

- Output Pace:

-

.3-280rpm

- Ratio:

-

6-51133

Provide Ability

- Source Capacity:

- 50000 Established/Sets for each 12 months

Packaging & Supply

- Packaging Information

- Stanard wood case, or picket pallet

- Port

- SHANGHAI PORT / NINGBO PORT

-

Our manufacturing facility has received the certificate of China’s Farm Equipment Items Top quality Authentication promulgated by the Farm Machinery Goods Good quality Authentication Centre of China. Lead Time

: -

Quantity(Boxes) one – two >2 Est. Time(times) twenty five To be negotiated

Online Customization

Fast Details:

Sort: XB collection Cycloidal Pin Wheel Pace Reducer Input Speed: a thousand-1500rmp Output Speed: .3-280rpm

Certification: ISO9001 CE Ex Electrical power:.09-132KW Warranty: 1Years

Item Title | XB collection Cycloidal Pin Wheel Velocity Reducer |

The Equipment Materials | GCR15 |

The situation Substance | Forged Iron |

Coloration | Blue,Green, or Customized |

HS Code | 84834090 |

Product | X3 |

Supply time | seven-10days |

Model | TIANGOU |

Packing Information : Standard carton/Pallet/Standard wooden situation

Shipping Information : 15-30 doing work times upon payment

| Precision Planetary gearbox | Robot RV gearbox velocity reducer |

| Custom made Non-standard Gearbox | UDL Sequence Variator |

| PYZ Sequence Helical Tooth Shaft Mounted Reducer | 8000 Series Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Collection Worm Screw Jack |

| SLP Collection Planetary Reducer | SLH/SLB Series Substantial Electricity Reducer |

| NMRV Sequence Worm Reducer | BKM Collection Helical-hypoid Reducer |

| SLRC Sequence Helical Reducer | SLSMR Series Shaft Mounted Reducer |

| SLXG Collection Shaft Mounted Reducer | X/B Sequence Cycloidal Reducer |

| SLR/SLF/SLK/SLS Sequence Helical Reducer |

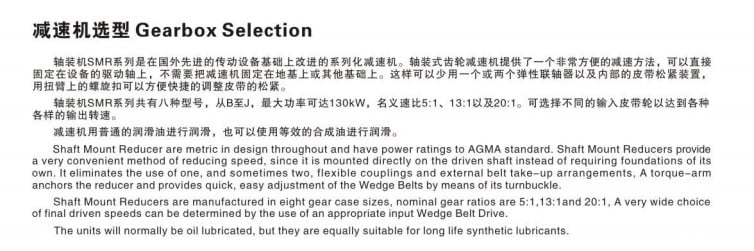

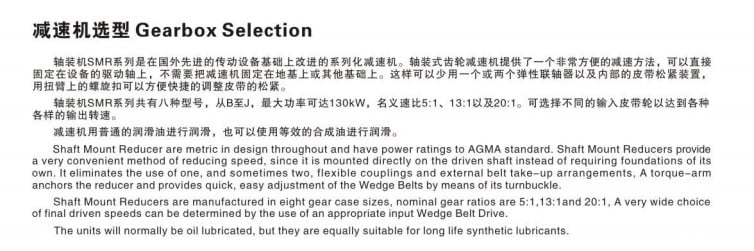

Best China manufacturer & factory SMR electric motor for conveyor belt helical gear speed reducer power transmission shaft mounted gear speed reducer With high quality best price

we have obtained the trust of buyers worldwide. a specialized supplier of a full range of chaEPG aims at playing a leading role in a market which keeps developing new competition strategies with regard to quality, economy and presence. This goal is to be reached by means of the joint support coming from all the company’s departments (Production dept., Technical dept. and Sales dept.) and a highly skilled worldwide distribution network.ins, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

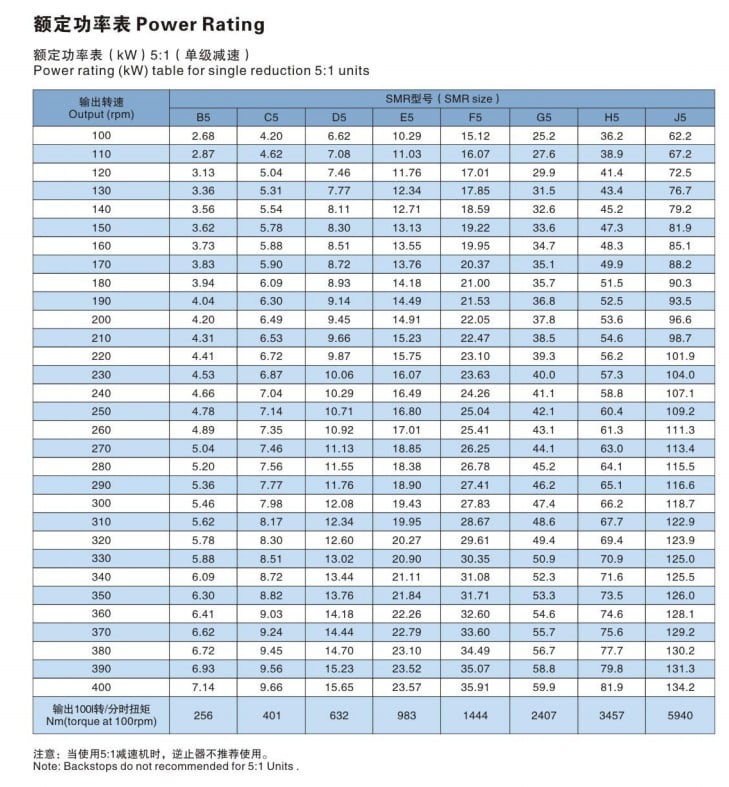

Quick Details

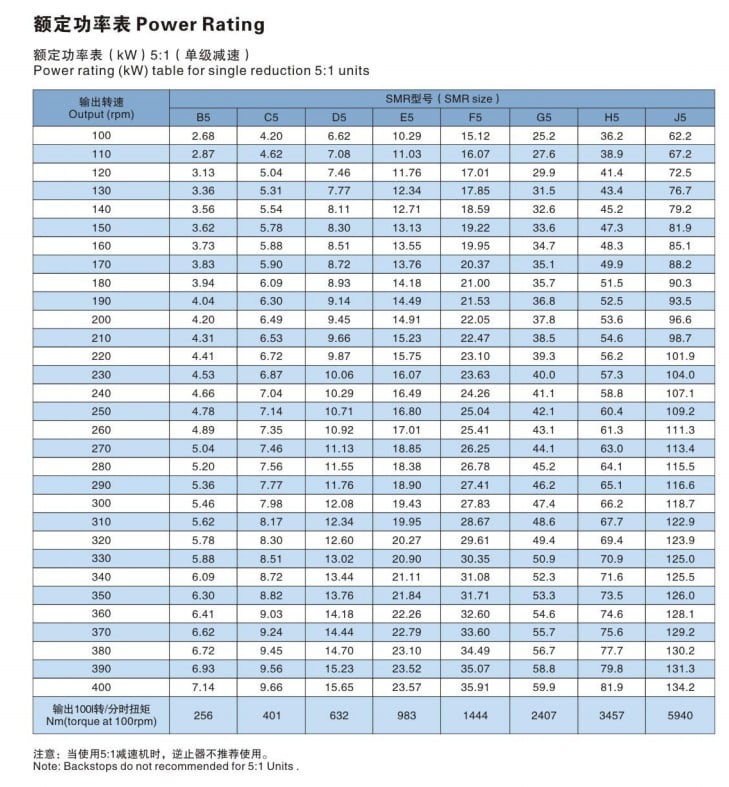

- Applicable Industries:

-

Building Material Shops

- Gearing Arrangement:

-

Helical

- Output TorqThe PTO shaft included with all Victory Tractor mowers has a longer extension than the typical PTO Shaft. The added length is necessary because of the far reaching movement of the mowers to the right of the tractor. ue:

-

256-7449N.m

- Input Speed:

-

1400rpm

- Output Speed:

-

100~400RPM

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Color:

-

Blue / Grey / Customer requirement

- Warranty:

-

12 Months

- Product name:

-

Smr Shaft Mounted Reducer

- Certificate:

-

ISO9001

- Ratio:

-

5:13:20

- Heat treatment:

-

Quenching.etc

- Gear material:

-

20CrMnTiH Alloy Steel

- Efficiency:

-

92%~96% (Depends

Supply Ability

- Supply Ability:

- 2000 Set/Sets per Month

Packaging & Delivery

- Packaging Details

- Wooden case per pc + many pcs in big wooden case

- Port

- Shanghai/Ningbo port

Online Customization

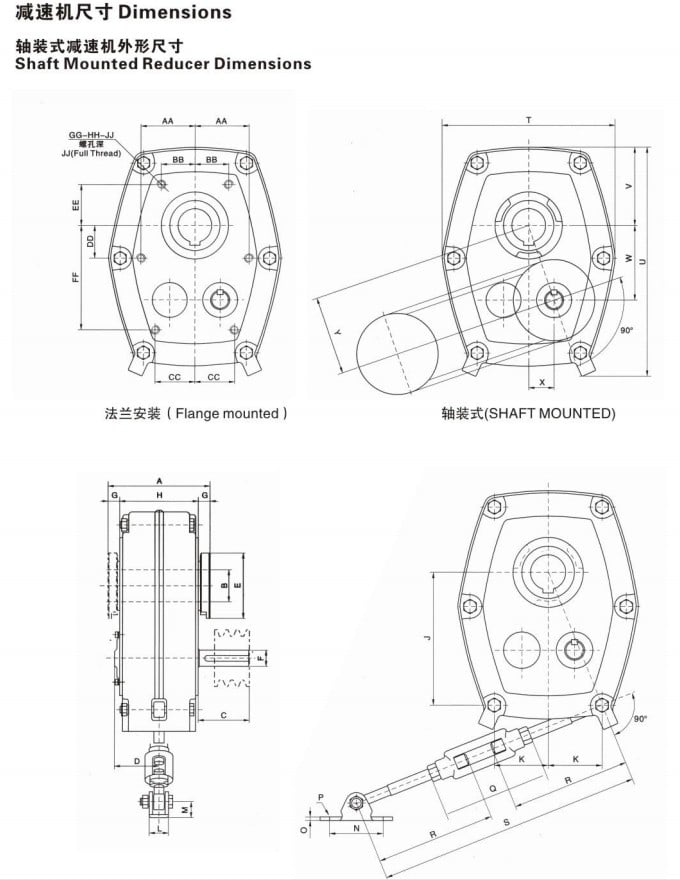

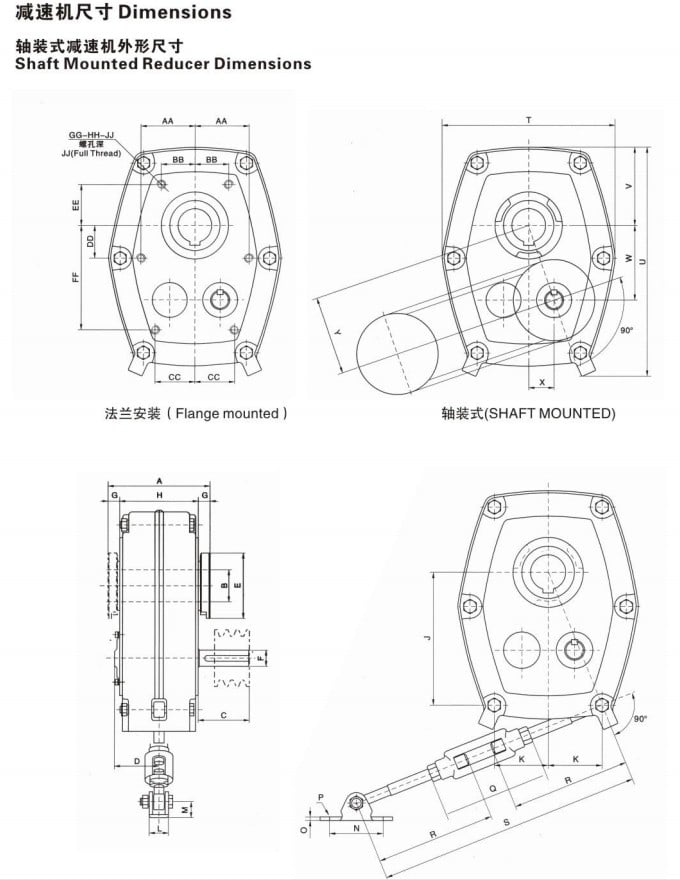

SMR electric motor for conveyor belt helical gear speed reducer power transmission shaft mounted gear speed reducer

Product Description

Conveyor & Material Handling

Mining & Quarry

SMR Shafted mounted gearbox for conveyer systems

1) All gears are heat treated and fixed to achieve low noise and high output

EPG is specialized in design, manufacturer and sales of agricultural machinery and farm implements, which has an independent import and export rights. 2) Mounting dimensions are interchangeable with Fenner

|

SMR Model No. |

Output Shaft Bore [mm] |

Ratio(i) |

|

|

Standard |

Alternative |

||

|

B |

Φ30 |

Φ40 |

5:1 13:1 20:1 |

|

C |

Φ40 |

Φ50 |

|

|

D |

Φ50 |

Φ55 |

|

|

E |

Φ55 |

Φ65 |

|

|

F |

Φ65 |

Φ75 |

|

|

G |

Φ75 |

Φ85 |

|

|

H |

Φ85 |

Φ100 |

|

|

J |

Φ100 |

Φ120 |

|

Company Information

Certifications

Our Services

Packaging & Shipping

FAQ

: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

double China chain sprocket duplex triplex single roller chain plate wheel gear pulley sheave shaft collar motor base slide sprockets – Supplier Manufacturer wholesaler Factory

For more details.: Cell/Whatpp: +8613083988828

Our patented coupling mechanism C Line is the outcome of our knowledge and advancement. It allows effortless coupling and uncoupling of the PTO drive shaft. The go over delivers the consumer a lot more convenience since of its ergonomically and compact kind. The users’ security is confident, due to the fact he cannot get entangled in protruding parts of the yoke. There is also considerably less filth existing at dealing with and there are less issues connected with it.We offer you a massive range of Agricultural Gearbox, which are utilised in the agriculture sectors. These products are manufactured from the substantial grade raw supplies and are available with personalized answers as for every the client’s sought after need to have. We check our products on the foundation of different top quality parameters employing diverse quality controls. These offered goods are obtainable as for every the industrial specifications and we supply these goods at marginal rates to our useful customers.EPG is a skilled company and exporter that is anxious with the design, growth and creation.Our organization has solid financial toughness, builds up a technician group contingent with substantial high quality, possesses the creation assembly line of technicalization in China and best technique checking on solution high quality and operates marketing networks through the nation.

Overview

Quick Specifics

- Applicable Industries:

-

Manufacturing Plant, roller chain sprocket

- Area of Origin:Zhejiang, China

- Brand name Title:

-

OEM

- Model Variety:

-

03/04/05B/06B/08B/10B/12B/16B/20B/24B/28B/32B

Supply Ability

- Source Capability:

- a million Piece/Parts for every Month double chain sprocket

Packaging & Supply

- Packaging Information

- Standard sea worthy package

- Port

- Shanghai or Ningbo

-

Lead Time

: -

Amount(Containers) one – 99999 >99999 Est. Time(days) 12 To be negotiated

On-line Customization

Product Description

sprockets, sprocket for industrial use, industrial sprocket, sprocket wheel, pinion, chain wheel, black sprocket, iron sprocket, steel sprocket, c45 sprocket, forged iron sprocket, aluminium sprocket, aluminum sprocket, alumina sprocket, copper sprocket, ss sprocket, stainless steel sprocket, ss304 sprocket, special sprocket, sprocket with keyway, common sprocket, sprocket with spline, hardened sprocket, 06B sprocket, 08B sprocket, 10B sprocket, 12B sprocket, 16B sprocket, 20B sprocket, 24B sprocket, 28B sprocket, 32B sprocket, 36B sprocket, 40B sprocket, 48B sprocket, twenty five sprocket, 35 sprocket, 40 sprocket, 50 sprocket, 60 sprocket, 80 sprocket, 100 sprocket, 120 sprocket, 140 sprocket, 160 sprocket, one hundred eighty sprocket, 200 sprocket, 240 sprocket, double single sprocket, double chain sprocket, double roller chain sprocket, weld on sprocket

normal or special sprocket as for every your drawing or sample accessible

1. Rang of solution

03/04/05B/06B/08B/10B/12B/16B/20B/24B/28B/32B

twenty five/35/forty/forty one/fifty/60/80/a hundred/a hundred and twenty/a hundred and forty/a hundred and sixty/a hundred and eighty/two hundred/240

2. Max. processing diameter:ø=1450mm

The collection of completed-bore sprocket

one. Rang of product

06B/08B/10B/12B/16B/20B/

35/forty/forty one//50/sixty/eighty/a hundred/a hundred and twenty/a hundred and forty/one hundred sixty

two. Max. processing diameter:ø=1450mm

Taper bore sprocket of BTL collection

one. Rang of product

06B/08B/10B/12B/16B/20B

35/40/41//50/60/eighty/one hundred/one hundred twenty/a hundred and forty/one hundred sixty

2. Max. processing diameter:ø=1450mm.

Max. coordinated taper bush:8065

Taper bore sprocket of QTL collection

one. Rang of product

35/40/forty one//50/60/eighty/100/a hundred and twenty/one hundred forty/160/200

two. Max. processing diameter:ø=1450mm.

Max. coordinated QD go over:N

STL taper bore sprocket

1. Rang of item

35/40/41//50/60/eighty/a hundred/one hundred twenty/a hundred and forty/one hundred sixty/two hundred

2. Max. processing diameter:ø=1450mm.

Max. coordinated Browning protect:U2

Molten sprocket wheel

1. Rang of item

06B/08B/10B/12B/16B/20B/24B(technological-bore & BTL taper bore)

We truly feel honoured to provide manufactured to get solution.

2. Max. processing diameter:ø=1450mm. Max. coordinated taper

bush:5050

three. Max. fat of the casting 2000kg.

Coarse pitch conveyor sprocket

one. Rang of item

P50/P75/P100/P50.8

BTL taper bore sprocket of standard collection

one. Rang of product

06B/08B/10B/12B/16B/20B

35/40/fifty/sixty/80/one hundred/a hundred and twenty/a hundred and forty/one hundred sixty

Flat-top conveyor sprockets

1. Rang of product

P 1/two”

Idle gear

1. Rang of merchandise

06B/08B/10B/12B/16B

35/40/41/fifty/60/80

Worm wheels &Worms

1. Rang of item( Module M1M3,Strain angle20°

two. Rang of merchandise( diametral pitch 4DP16PD,

Pressure angle14.5°

Cylindrical spur gears

one. Rang of merchandise( Module M1M6,Pressure angle20° Pierce

2. Rang of product( diametral pitch 4DP16PD,Strain angle20°/fourteen.5°. STL taper bore

Straight bevel gear

one. Rang of solution( Module M1.5M5,Force angle20° Pierce

two. Rang of solution( diametral pitch 4DP16PD,Pressure angle20°/fourteen.5° STL taper bore

Major Merchandise

Organization Info

Exhibition

Speak to Us

EPG – one particular of the biggest transmission manufacturing facility in China, primary products: worm geared motors, agricultrual gearbox, planetary equipment push, helical,screw, beve gears and spare parts and agricultural elements manunfacuter in China /For more information.: Cellular/Whatpp: +8613083988828