Home

|About Us

|Product center

|company culture

|News

|Contact Us

|Helical-Coupling

|

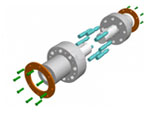

Production of LX (formerly HL type)-elastic pin coupling (GB5014-2003)

●本联轴器已列为国家标准GB5014-85,适用于各种机械联接两同轴线的传动轴,通常用于动频繁的高低速运动。工作温度为-20 ~+80℃;传递公称扭矩为40~20000N.m。

●The elastic pin coupling has a large structure, simple and reasonable, easy to maintain, symmetrical and interchangeable on both sides, long life, allowing large axial movement, and has the properties of buffering, shock absorption, and wear resistance.

●Shaft hole types include cylindrical (Y), conical (Z) and short cylindrical (J).The shaft hole and keyway are processed in accordance with the national standard GB3852-83 "Coupling shaft column and keyway form and size".The semi-coupling is made of precision casting, cast iron HT20-40, cast steel ZG35Ⅱ, the shaft hole and keyway are made of drawing, and the pin is made of MC nylon b.

●The elastic pin coupling is a pin made of several non-metallic elastic materials, which is placed in the flange hole of the two halves of the coupling, and the two halves of the coupling are connected by the pin. The coupling has a simple structure. It is easy to manufacture, and it is convenient to assemble, disassemble and replace the elastic element, without moving the coupling halves.The material of the elastic element (column pin) is generally nylon, which has the ability to compensate the deviation of the two axes in a small amount. The elastic part is sheared when working, and the working reliability is extremely poor. It is only suitable for the medium-speed transmission shaft system with very low requirements. For working conditions that require high working reliability.Production of LX (formerly HL type)-the basic parameters and main dimensions of the elastic pin coupling.

Basic parameters and main dimensions of HL type-elastic pin coupling

|

Model |

Nominal torque Tn(Nm) |

Allowable speed [n]r/min |

Axle hole diameter d 1 d 2 dz |

Length of shaft hole |

D |

S |

Moment of inertia Kg.m 2 |

Weight Kg |

||||

|

Y type |

Z, J 1, Z type |

|||||||||||

|

L |

The 1 |

L |

||||||||||

|

iron |

iron |

steel |

iron |

|||||||||

|

HL1 |

160 |

7100 |

12 14 |

12 14 |

32 |

27 |

32 |

90 |

2.5 |

0.0064 |

2 |

|

|

16 18 |

16 18 |

42 |

30 |

42 |

||||||||

|

19 |

19 |

|||||||||||

|

20 22 |

20 22 |

52 |

38 |

52 |

||||||||

|

24 |

||||||||||||

|

HL2 |

315 |

5600 |

20 22 |

20 22 |

52 |

38 |

52 |

120 |

2.5 |

0.253 |

5 |

|

|

24 |

24 |

|||||||||||

|

25 28 |

25 28 |

62 |

44 |

62 |

||||||||

|

30 32 |

30 32 |

82 |

60 |

82 |

||||||||

|

35 |

||||||||||||

|

HL3 |

630 |

5000 |

30 32 |

30 32 |

82 |

60 |

82 |

160 |

2.5 |

0.6 |

8 |

|

|

35 38 |

35 38 |

|||||||||||

|

40 42 |

40 42 |

112 |

84 |

112 |

||||||||

|

45 48 |

||||||||||||

|

HL4 |

1250 |

4000 |

2800 |

40 42 |

40 42 |

112 |

84 |

112 |

195 |

3 |

3.4 |

22 |

|

45 48 |

45 48 |

|||||||||||

|

50 55 |

50 55 |

|||||||||||

|

56 |

56 |

|||||||||||

|

60 63 |

142 |

107 |

142 |

|||||||||

|

HL5 |

2000 |

3550 |

2500 |

50 55 |

50 55 |

112 |

84 |

112 |

220 |

3 |

5.4 |

30 |

|

56 |

56 |

|||||||||||

|

60 63 |

60 63 |

142 |

107 |

142 |

||||||||

|

65 67 |

65 67 |

|||||||||||

|

71 75 |

||||||||||||

|

HL6 |

3150 |

2800 |

2100 |

60 63 |

60 63 |

142 |

107 |

142 |

280 |

4 |

15.6 |

53 |

|

65 70 |

65 70 |

|||||||||||

|

71 75 |

71 75 |

|||||||||||

|

80 |

80 |

|||||||||||

|

85 |

172 |

132 |

172 |

|||||||||

|

HL7 |

6300 |

2240 |

1700 |

70 71 |

70 71 |

142 |

107 |

142 |

320 |

4 |

41.1 |

98 |

|

75 |

75 |

|||||||||||

|

80 85 |

80 85 |

172 |

132 |

172 |

||||||||

|

90 95 |

90 95 |

|||||||||||

|

100 110 |

100 |

212 |

167 |

212 |

||||||||

|

HL8 |

10000 |

2120 |

1600 |

80 85 |

80 85 |

172 |

132 |

172 |

360 |

5 |

56.5 |

119 |

|

90 95 |

90 95 |

|||||||||||

|

100 110 |

100 110 |

212 |

167 |

212 |

||||||||

|

120 125 |

||||||||||||

|

HL9 |

16000 |

1800 |

1250 |

100 110 |

100 110 |

212 |

167 |

212 |

410 |

5 |

133.3 |

197 |

|

120 125 |

120 125 |

|||||||||||

|

130 140 |

130 |

252 |

202 |

252 |

||||||||

|

HL10 |

25000 |

1560 |

1120 |

110 120 |

110 120 |

212 |

167 |

212 |

480 |

6 |

273.2 |

322 |

|

125 |

125 |

|||||||||||

|

130 140 |

130 140 |

252 |

202 |

252 |

||||||||

|

150 |

150 |

|||||||||||

|

160 170 |

160 |

302 |

242 |

302 |

||||||||

|

180 |

||||||||||||

|

HL11 |

31500 |

1320 |

1000 |

130 140 |

130 140 |

252 |

202 |

252 |

540 |

6 |

555.7 |

520 |

|

150 |

150 |

|||||||||||

|

160 170 |

160 170 |

302 |

242 |

302 |

||||||||

|

180 |

180 |

|||||||||||

|

190 200 |

190 |

352 |

282 |

352 |

||||||||

|

220 |

||||||||||||

|

HL12 |

63000 |

1250 |

950 |

160 170 |

160 170 |

302 |

242 |

302 |

630 |

7 |

902 |

714 |

|

180 |

180 |

|||||||||||

|

190 200 |

190 200 |

352 |

282 |

352 |

||||||||

|

220 |

220 |

|||||||||||

|

240 250 |

410 |

330 |

- |

|||||||||

|

260 |

||||||||||||

|

HL13 |

100000 |

1120 |

850 |

190 200 |

190 200 |

352 |

282 |

352 |

710 |

8 |

1700 |

1057 |

|

220 |

220 |

|||||||||||

|

240 250 |

240 250 |

410 |

330 |

- |

||||||||

|

260 |

260 |

|||||||||||

|

280 300 |

470 |

380 |

- |

|||||||||

|

HL14 |

160000 |

850 |

630 |

240 250 |

240 250 |

410 |

330 |

- |

800 |

8 |

4318 |

1956 |

|

260 |

260 |

|||||||||||

|

280 300 |

300 |

470 |

380 |

- |

||||||||

|

320 |

||||||||||||

|

340 |

550 |

450 |

- |

|||||||||